The Marketplace is Improving; Are You Sure You Are Working With The Right Vendors?

The marketplace seems to be picking up for contractors. Many are reporting increased leads and sales. With increased demand for the products contractors need to build their projects we will definitely see supply and demand challenges with local lumberyards, the big boxes and specialty product vendors. This supply and demand challenge is one of the reasons many in the construction industry are predicting as much as a 25% increase in cost on many building products. Although contractors need to be aware of these increases as they price their projects, I suggest they also need to make sure the vendors and suppliers they purchase their materials and products from will be prepared for the increased demand.

If you are a contractor who has been buying on price from vendors who have been selling on low price to get your business, you might want to think twice. If that vendor has a good business, low or no debt and is using efficient business systems and technology to keep their costs low, you may be OK. But if your vendor has very high debt, has cut back on staffing, equipment and service, just so they could sell at low prices, their business may not be prepared for a surge in sales as the economy improves.

Choosing and keeping the right building product dealers for your business and your customers

Here are some things to think about regarding the vendors you are currently using. This same list can also help you decide which vendor or vendors you should work with going forward:

- Many lumberyards and specialty dealers are short staffed. To save money and to stay in business many of these businesses have reduced staff during the recession and often times the people they let go were the higher paid employees. If this is a tactic any of your suppliers used they may have let go many of their most knowledgeable staff. The remaining staff, often less skilled and far less knowledgeable about building products, construction and contractors, will be challenged to serve contractors as the number of contractors doing work and buying materials picks up.

Building product suppliers who have high debt may not be able to finance the cost of increasing their inventories to keep up with the predicted supply and demand challenges as the economy improves. If this happens at your supplier you may find that many products, even common commodities like framing lumber, will be out of stock. Imagine going to the lumberyard first thing in the morning to get the materials you need to frame a deck or reframe that kitchen, only to find out you can’t get what you need. To keep working that day you might have to pay for longer lengths than you need, or might even have to drive to a different supplier in the hopes that they will have what you need so you can work that day. Remember, if you lose two hours chasing materials, in reality you also lost two hours of productive time on the job. That would mean you lost a total of four hours you could have billed your client for if the materials were already at the jobsite.

Building product suppliers who have high debt may not be able to finance the cost of increasing their inventories to keep up with the predicted supply and demand challenges as the economy improves. If this happens at your supplier you may find that many products, even common commodities like framing lumber, will be out of stock. Imagine going to the lumberyard first thing in the morning to get the materials you need to frame a deck or reframe that kitchen, only to find out you can’t get what you need. To keep working that day you might have to pay for longer lengths than you need, or might even have to drive to a different supplier in the hopes that they will have what you need so you can work that day. Remember, if you lose two hours chasing materials, in reality you also lost two hours of productive time on the job. That would mean you lost a total of four hours you could have billed your client for if the materials were already at the jobsite. Lumber and building materials dealers who cut back on staff may also be challenged to help you sell to your customers. If you had a customer who wanted to see the door, cabinets or windows you recommend, will you be able to send them down to your local supplier to see the products they are looking for? What is the condition of the showroom? Is there going to be anyone there to make and take the time to meet with and help your customer? Will the person working at that dealer have the sales skills, product knowledge and knowledge about you and your business to help you make the sale?

Lumber and building materials dealers who cut back on staff may also be challenged to help you sell to your customers. If you had a customer who wanted to see the door, cabinets or windows you recommend, will you be able to send them down to your local supplier to see the products they are looking for? What is the condition of the showroom? Is there going to be anyone there to make and take the time to meet with and help your customer? Will the person working at that dealer have the sales skills, product knowledge and knowledge about you and your business to help you make the sale?

The risks of low price

Selling on low price typically puts any business on a path to failure. Sure, it may seem to help things at first when money gets tight. However, unless they can ramp up their businesses, and do so before the market place improves, they will be forced to play a game of keep up and catch up as their customers’ needs and demands for products and service increases. Working with a low price vendor might seem attractive, but can you be confident they will have what you need when you needed it? If they require a deposit on special order items, are you confident they will still be in business by the time you expect delivery of what you ordered? What will your customers think of you and your business if their project start date gets delayed and or the completion date gets extended because you can’t get what you need from your vendors to keep their project and your business on schedule?

Summary

Choosing the wrong vendors by saving a few bucks on materials may cost you and your construction business lots of wasted time, money and the valuable referrals your business has enjoyed from what used to be happy customers. I highly recommend you choose your vendors wisely!

At a recent Remodeler Summit event I participated in for

At a recent Remodeler Summit event I participated in for

At a tour of

At a tour of

Both examples above can help contractors earn more money in less time. Both examples offer ways contractors can get more work done without having to add any additional talents or skills to their crews. Both examples also eliminate or reduce the need to find and bring in sub contractors to do work the contractor’s own crews either don’t have the talents for or might not be cost effective at doing.

Both examples above can help contractors earn more money in less time. Both examples offer ways contractors can get more work done without having to add any additional talents or skills to their crews. Both examples also eliminate or reduce the need to find and bring in sub contractors to do work the contractor’s own crews either don’t have the talents for or might not be cost effective at doing.

Sequential learners learn best when information is presented to them in logical step by step order. By presenting information to them in the order tasks should be completed, they can see how one step prepares for the next and or how subsequent steps are dependent on the previous step. These employees are typically successful at repetitive activities, even activities that require a high level of skill. Examples could include install crown moldings or estimating projects that can be done using a unit cost method. However sequential learners might not make for good lead carpenters at a business where every project is different and or projects are highly detailed. A sequential learner lead carpenter may be challenged if the business does not provide adequate project specifications and facilitated planning opportunities before the project begins. Also, a sequential learner might not have success selling Design/Build projects to prospects who are global learners.

Sequential learners learn best when information is presented to them in logical step by step order. By presenting information to them in the order tasks should be completed, they can see how one step prepares for the next and or how subsequent steps are dependent on the previous step. These employees are typically successful at repetitive activities, even activities that require a high level of skill. Examples could include install crown moldings or estimating projects that can be done using a unit cost method. However sequential learners might not make for good lead carpenters at a business where every project is different and or projects are highly detailed. A sequential learner lead carpenter may be challenged if the business does not provide adequate project specifications and facilitated planning opportunities before the project begins. Also, a sequential learner might not have success selling Design/Build projects to prospects who are global learners. On the other hand global learners can take in random bits of information about a project or task and can quickly connect the dots between that information to assess a situation or assemble a solution on their own by quickly understanding the connections between those bits of information. These employees can be very successful at job positions like handyman repairs, troubleshooting roof leaks and or gathering information from Design/Build clients who know why they want to do a project but might not know yet how to get started or what needs to be considered. Also consider these employees might quickly become bored with repetitive activities or duties.

On the other hand global learners can take in random bits of information about a project or task and can quickly connect the dots between that information to assess a situation or assemble a solution on their own by quickly understanding the connections between those bits of information. These employees can be very successful at job positions like handyman repairs, troubleshooting roof leaks and or gathering information from Design/Build clients who know why they want to do a project but might not know yet how to get started or what needs to be considered. Also consider these employees might quickly become bored with repetitive activities or duties. Installing windows these days requires building science knowledge and an understanding of installation options regarding the methods and products that can be used. A lead carpenter who is a global learner can be real good at understanding the science considerations and specifying appropriate installation details. With those project specific details in hand a sequential learner carpenter can then be instructed by that lead carpenter, right at the jobsite, on how to install all the windows. While the carpenter installs the windows the lead carpenter can be making the materials list for the next phase of the job so the materials will be ready for the carpenter when the carpenter is done installing the windows. Unlike a production manager driven production system, because a lead carpenter driven system is being used, the global learner who specified the installation method is at the job site to oversee and if needed trouble shoot the efforts of the carpenter. With a production manager driven system, after being instructed, the sequential learner carpenter might be on his own without anyone overseeing his or her activities to be sure the windows are being installed correctly.

Installing windows these days requires building science knowledge and an understanding of installation options regarding the methods and products that can be used. A lead carpenter who is a global learner can be real good at understanding the science considerations and specifying appropriate installation details. With those project specific details in hand a sequential learner carpenter can then be instructed by that lead carpenter, right at the jobsite, on how to install all the windows. While the carpenter installs the windows the lead carpenter can be making the materials list for the next phase of the job so the materials will be ready for the carpenter when the carpenter is done installing the windows. Unlike a production manager driven production system, because a lead carpenter driven system is being used, the global learner who specified the installation method is at the job site to oversee and if needed trouble shoot the efforts of the carpenter. With a production manager driven system, after being instructed, the sequential learner carpenter might be on his own without anyone overseeing his or her activities to be sure the windows are being installed correctly.

Earlier this week I presented a webinar hosted by

Earlier this week I presented a webinar hosted by  As a contractor please don't come in with a bad attitude.

As a contractor please don't come in with a bad attitude. I shared with the attendees that this was one of those things I have been working on for years; trying to help contractors and their employees improve their processes and even use checklists to help make sure everything is on the job site before it is needed. Here’s the thing; making multiple trips cost both the contractor and the lumber dealer money that could be better invested elsewhere. Plus, if as a contractor your employees aren’t smart enough or don’t care enough to plan ahead, it might be time to find new employees who can and will plan ahead. If you or your employees need training to help curb this problem, consider attending this production workshop.

I shared with the attendees that this was one of those things I have been working on for years; trying to help contractors and their employees improve their processes and even use checklists to help make sure everything is on the job site before it is needed. Here’s the thing; making multiple trips cost both the contractor and the lumber dealer money that could be better invested elsewhere. Plus, if as a contractor your employees aren’t smart enough or don’t care enough to plan ahead, it might be time to find new employees who can and will plan ahead. If you or your employees need training to help curb this problem, consider attending this production workshop. Again, I think this is one that both the lumber dealer and the contractor can share responsibility in. Whoever takes the order at the yard needs to ask for directions and should also probably make a point of always asking if there is anything they should know that would help the driver find the right location for the delivery. At the same time I think contractors should also be proactive by speaking up and offering advice if they know their job site is difficult to find or access. Posting a job sign in a visible location could be helpful. Also, if there’s no room to turn around to strategically drop a load where you want it, why not suggest that the driver back in from the street when you’re placing your order.

Again, I think this is one that both the lumber dealer and the contractor can share responsibility in. Whoever takes the order at the yard needs to ask for directions and should also probably make a point of always asking if there is anything they should know that would help the driver find the right location for the delivery. At the same time I think contractors should also be proactive by speaking up and offering advice if they know their job site is difficult to find or access. Posting a job sign in a visible location could be helpful. Also, if there’s no room to turn around to strategically drop a load where you want it, why not suggest that the driver back in from the street when you’re placing your order.

Help them get mentally prepared: Let them know what to expect they will live through while the construction is under way. Tell them about things that might affect them like the noise, the dust, shutting off their water, change orders and the decisions that come with final selections and unanticipated challenges. Just as a doctor would do with patients regarding medications, a good remodeler will warn clients that it is likely there might be side effects experienced during the remodeling process. By doing so clients can recognize the warning signs so they will be able to mentally and physically adjust. Also, my experience was that by discussing these realities in advance, the fatigue might not set in as early, or at least would not be as significant, as early, as it might be if my team had not warned them.

Help them get mentally prepared: Let them know what to expect they will live through while the construction is under way. Tell them about things that might affect them like the noise, the dust, shutting off their water, change orders and the decisions that come with final selections and unanticipated challenges. Just as a doctor would do with patients regarding medications, a good remodeler will warn clients that it is likely there might be side effects experienced during the remodeling process. By doing so clients can recognize the warning signs so they will be able to mentally and physically adjust. Also, my experience was that by discussing these realities in advance, the fatigue might not set in as early, or at least would not be as significant, as early, as it might be if my team had not warned them. Help them get physically prepared: Living through the remodeling process can be much easier with some preparation. For example, remind customers they will not be able to cook while you remodel their kitchen. Suggest they consider cooking and freezing easy to microwave meals and or collect take out menus before you start their kitchen renovation. Some remodelers have told me they actually provide their clients recipe books and or a collection of local restaurant menus to help with this. If you are renovating their only bathroom as part of a project, ask how they plan to deal without a toilet for a few days or more. They may not have even thought about such realities. Maybe you or they can even set up temporary spaces to tide them over until they get their homes and their lives back.

Help them get physically prepared: Living through the remodeling process can be much easier with some preparation. For example, remind customers they will not be able to cook while you remodel their kitchen. Suggest they consider cooking and freezing easy to microwave meals and or collect take out menus before you start their kitchen renovation. Some remodelers have told me they actually provide their clients recipe books and or a collection of local restaurant menus to help with this. If you are renovating their only bathroom as part of a project, ask how they plan to deal without a toilet for a few days or more. They may not have even thought about such realities. Maybe you or they can even set up temporary spaces to tide them over until they get their homes and their lives back.

Contractors who try to job cost inside QuickBooks at the level of 2x6’s and specific products (Kohler faucet K-13490-CP) produce three problems:

Contractors who try to job cost inside QuickBooks at the level of 2x6’s and specific products (Kohler faucet K-13490-CP) produce three problems: Contractors who continually add job-specific line items in QuickBooks invoices (ex: “repair Jones front porch step”, “Replace damaged shower tile”, “Add backsplash”) produce these two problems:

Contractors who continually add job-specific line items in QuickBooks invoices (ex: “repair Jones front porch step”, “Replace damaged shower tile”, “Add backsplash”) produce these two problems:

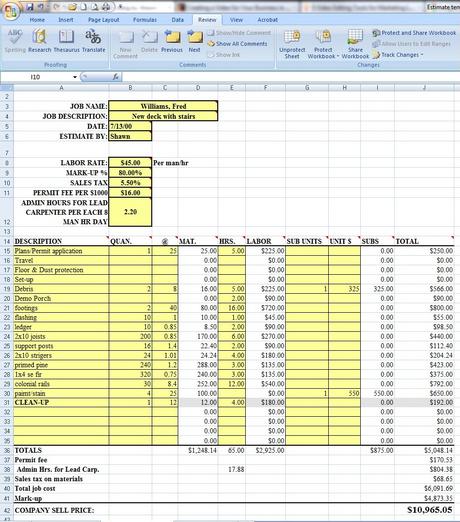

So, when you determine the burdened hourly rate to use in your estimates and for job costing you can't be guessing. To get the accurate rate you must divide the total annual cost to compensate and support each employee by the number of hours he or she will be working producing income. For the example above, you must collect enough money in 1940 hours of productive time so you will have enough money to pay the employee for 2080 hours. Non-productive time and other labor related expenses are easily calculated into a burdened labor rate using a spreadsheet like the one shown above.

So, when you determine the burdened hourly rate to use in your estimates and for job costing you can't be guessing. To get the accurate rate you must divide the total annual cost to compensate and support each employee by the number of hours he or she will be working producing income. For the example above, you must collect enough money in 1940 hours of productive time so you will have enough money to pay the employee for 2080 hours. Non-productive time and other labor related expenses are easily calculated into a burdened labor rate using a spreadsheet like the one shown above. Recently there has been a lot of buzz around the remodeling and home improvement industries regarding OSHA enforcement.

Recently there has been a lot of buzz around the remodeling and home improvement industries regarding OSHA enforcement. OSHA requirements do not apply if you are the business owner and only work alone.

OSHA requirements do not apply if you are the business owner and only work alone. Below is short a list of things contractors should consider if they want to be ready when an OSHA Inspector drives by and or stops in to check out your job site.

Below is short a list of things contractors should consider if they want to be ready when an OSHA Inspector drives by and or stops in to check out your job site. Knowing what to charge clients for the work you do is often the difference between long term success and eventual failure for the business. Many contractors look at estimating simply as a way to determine the cost of a project. In the traditional design-bid model of project delivery, this simplistic approach may work, assuming your sell price generates enough gross profit to cover your overhead and profit requirements. However, if you’re doing design/build, and your current estimating system is limited to only producing the number you charge clients for a project, you may be missing out on many other possible benefits.

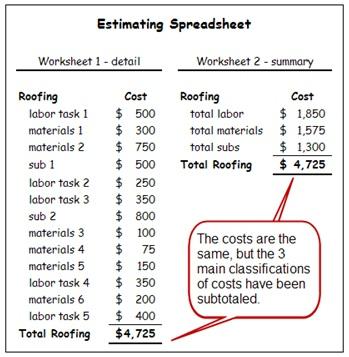

Knowing what to charge clients for the work you do is often the difference between long term success and eventual failure for the business. Many contractors look at estimating simply as a way to determine the cost of a project. In the traditional design-bid model of project delivery, this simplistic approach may work, assuming your sell price generates enough gross profit to cover your overhead and profit requirements. However, if you’re doing design/build, and your current estimating system is limited to only producing the number you charge clients for a project, you may be missing out on many other possible benefits. If you think of Design/Build as a way of doing business, your estimating system must become a tool that facilitates how you do business, not just a way to get to the price. Here are several ways a Design/Builder or a remodeler can maximize the potential of the method and system used to do estimating:

If you think of Design/Build as a way of doing business, your estimating system must become a tool that facilitates how you do business, not just a way to get to the price. Here are several ways a Design/Builder or a remodeler can maximize the potential of the method and system used to do estimating:

Many expect Workers Compensation rates to increase significantly this year. The MA Workers Comp Rating and Inspection Bureau has recently applied for an average rate increase of 19.3%. According to the Insurance Journal, Commissioner Joseph Murphy will be holding a public meeting on March 30th on this request.

Many expect Workers Compensation rates to increase significantly this year. The MA Workers Comp Rating and Inspection Bureau has recently applied for an average rate increase of 19.3%. According to the Insurance Journal, Commissioner Joseph Murphy will be holding a public meeting on March 30th on this request.