Update On The Lowes 2X4 Story and Controversy

Last week on September 9, 2014 I posted a blog titled California Judge May Have Created Huge Challenges for Contractors. At that time the information reported indicated that a California Superior Court judge by the name of Paul M. Haakenson had ordered Lowes to pay $1.6 million dollars for selling 2x4’s that are not really 2” x 4”. The story and my blog caught quite a bit of attention in the construction and building materials industries. Additional information has now surfaced.

Some clarifications

I had originally found the information in an article posted to ProSales magazine, a publication for professional building products dealers. Remodeling magazine recently posted an update about the story, offering some clarifications provided by the West Coast Lumber & Building Material Association (WCLBMA). In the article WCLBMA clarified the $1.6 million final judgment Lowe's reached with the State of California appears, at least in part, to involve labeling certain non-wood products as wood as well as the incorrect labeling of certain other lumber products.

In an August 27th press release by Marin County, the county where a local weights and measures division visited one of Lowes’ retail store locations, said the district attorneys' civil enforcement action claimed that "Lowe’s stores throughout the state unlawfully advertised structural dimensional building products for sale and those advertisements stated, contained, and described product dimensions that were not the actual product dimensions". The press release also states; “The judgment requires Lowe's to immediately remove products from sale or correct false, misleading, deceptive or inaccurate product descriptions when Lowe's knows or should know that the product descriptions are untrue or misleading”.

Don't blame the source

It would appear that in the original interview ProSales had with Lowes about the story the fact that Lowes was selling 2x4’s that did not meet the standard accepted size of 1 ½” x 3 ½” was a detail left out of the interview. I say this with a high level of confidence because I find ProSales to be consistently accurate and the magazine editor, Craig Webb, does a great job vetting the information being published.

It would appear that in the original interview ProSales had with Lowes about the story the fact that Lowes was selling 2x4’s that did not meet the standard accepted size of 1 ½” x 3 ½” was a detail left out of the interview. I say this with a high level of confidence because I find ProSales to be consistently accurate and the magazine editor, Craig Webb, does a great job vetting the information being published.

Do contractors still have plenty of reason for concern?

On the other hand I and many of the commenters at my blog are still concerned about the ruling details Lowes and other retailers must now follow. According to another ProSales article Judge Haakenson’s order lists the following three main rules for the retailer to follow going forward:

- "Common descriptions" must be followed by actual dimensions and labeled as such. For instance, a 2x4 must be followed with a disclaimer that the wood is actually 1.5-inches by 3.5-inches and include a phrase equal or similar to "actual dimensions."

- "Popular or common product description," like the word 2x4, must be "clearly described as 'popular name,' 'popular description,' or 'commonly called.'"

- Dimension descriptions are required to use the "inch-pound unit", meaning they must include abbreviations such as "in., ft., or yd.," and can't use symbols like ' or '' to denote measurements.

The concern I am expressing is if these rules apply to retailers will they also apply to contractors? If they do, or eventually will, contractors in California and the rest of the country may also run into challenges not only with the government, but also with their customers. Perhaps trade associations such as NAHB and NARI should proactively seek out the answer to this question to help guide and protect their members and the rest of the construction industry. The RRP Rule came about because our industry didn’t proactively deal with the hazards of lead during construction on its own before the government stepped in and dictated regulations many do not agree with.

The concern I am expressing is if these rules apply to retailers will they also apply to contractors? If they do, or eventually will, contractors in California and the rest of the country may also run into challenges not only with the government, but also with their customers. Perhaps trade associations such as NAHB and NARI should proactively seek out the answer to this question to help guide and protect their members and the rest of the construction industry. The RRP Rule came about because our industry didn’t proactively deal with the hazards of lead during construction on its own before the government stepped in and dictated regulations many do not agree with.

Perhaps this case against Lowes can serve as a warning and the industry can get out ahead of what the government could require of contractors. If these are or do become requirements contractors must follow perhaps the trade associations and industry publications can inform contractors before they experience costly challenges that could put them out of business.

What are your thoughts?

Are you concerned enough to ask your trade association to look into this?

Note:

Click here for an update on this story

The same is actually true for most Americans. According to

The same is actually true for most Americans. According to  Most construction business owners I speak with haven’t done any retirement planning. In fact 56% of American workers haven’t bothered to figure how much they’ll need to retire comfortably either. (Source: Employee Benefit Research Institute) How then could these contractors even know how much money they will need to retire and when they can actually retire? For these contractors I am pretty confident they won’t have what they need.

Most construction business owners I speak with haven’t done any retirement planning. In fact 56% of American workers haven’t bothered to figure how much they’ll need to retire comfortably either. (Source: Employee Benefit Research Institute) How then could these contractors even know how much money they will need to retire and when they can actually retire? For these contractors I am pretty confident they won’t have what they need. If earning a wage isn’t earning you enough to retire on, you might want to learn how to become a real business owner.

If earning a wage isn’t earning you enough to retire on, you might want to learn how to become a real business owner.

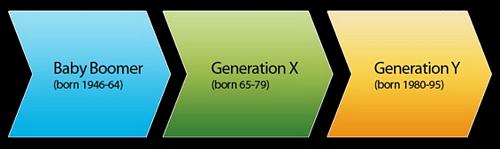

LBM Dealers and the distributors that supply Gen Y will need to make many changes to their business models and tactics. In order to successfully complete and support those changes they will need to upgrade both their staff and their technology. Here are a few quotes from Gen Y contractors that should help motivate both to get going before it’s already too late:

LBM Dealers and the distributors that supply Gen Y will need to make many changes to their business models and tactics. In order to successfully complete and support those changes they will need to upgrade both their staff and their technology. Here are a few quotes from Gen Y contractors that should help motivate both to get going before it’s already too late:

One thing that remained fairly constant during this evolution was who the contractors were and how they did business. For decades the majority of contractors operated their businesses as technicians. They thought of themselves as contractors, not construction business owners. The joy of building things and advancing their trade skills where the driving factors that made them who they were. As a result of this mentality, and the fact that there was almost always way more work available than contractors to do it, they could command profitable prices. And unfortunately, at the same time, they could also get by with poor business practices in the areas of sales, marketing and accounting.

One thing that remained fairly constant during this evolution was who the contractors were and how they did business. For decades the majority of contractors operated their businesses as technicians. They thought of themselves as contractors, not construction business owners. The joy of building things and advancing their trade skills where the driving factors that made them who they were. As a result of this mentality, and the fact that there was almost always way more work available than contractors to do it, they could command profitable prices. And unfortunately, at the same time, they could also get by with poor business practices in the areas of sales, marketing and accounting.

Fast delivery of that one joist hanger you’re missing so you can put the floor sheathing down and get the wall framing going

Fast delivery of that one joist hanger you’re missing so you can put the floor sheathing down and get the wall framing going I first came across this topic in a

I first came across this topic in a

Second is that the supply chain is finally spending money again on marketing to and investing in their remodeling contractor customers. Although still not as busy as they used to be, trade shows this past year have grow in size again as more manufacturers and distributors are back participating at the shows. Also, since about early this past summer, the number of manufacturers, distributors, dealers and trade associations contacting me about speaking at their events has also dramatically picked up. The supply chain is once again spending money to educate their staff as well as their contractor customers, as a way to grow their businesses as well as their customers’.

Second is that the supply chain is finally spending money again on marketing to and investing in their remodeling contractor customers. Although still not as busy as they used to be, trade shows this past year have grow in size again as more manufacturers and distributors are back participating at the shows. Also, since about early this past summer, the number of manufacturers, distributors, dealers and trade associations contacting me about speaking at their events has also dramatically picked up. The supply chain is once again spending money to educate their staff as well as their contractor customers, as a way to grow their businesses as well as their customers’.

think sums things up

think sums things up

Because EPA did not do an accurate estimate of program costs and revenues when they set their original fees, money coming in to support rule administration is not coming anywhere close to the actual costs. If EPA were a for profit business they would already have gone out of business when it comes to RRP. But, because the EPA and its leadership are not held to the same standards as for-profit businesses and business leaders, not only will they be allowed to continue operations, those at EPA who are responsible for the RRP rule get to keep their jobs and paychecks, despite such dismal performance. And, rather than concentrate on fixing their business plan to create financial health, EPA can simply charge their customers more money. The problem is that their customers, those who must comply with the rule, do not have any other options they can choose from to do business with.

Because EPA did not do an accurate estimate of program costs and revenues when they set their original fees, money coming in to support rule administration is not coming anywhere close to the actual costs. If EPA were a for profit business they would already have gone out of business when it comes to RRP. But, because the EPA and its leadership are not held to the same standards as for-profit businesses and business leaders, not only will they be allowed to continue operations, those at EPA who are responsible for the RRP rule get to keep their jobs and paychecks, despite such dismal performance. And, rather than concentrate on fixing their business plan to create financial health, EPA can simply charge their customers more money. The problem is that their customers, those who must comply with the rule, do not have any other options they can choose from to do business with.  The report pointed out three issues contributing to the EPA’s unrecovered costs.

The report pointed out three issues contributing to the EPA’s unrecovered costs.

How about before any real-estate is sold why not require a comprehensive inspection and inventory of the home be done? By doing so we could document the condition and configuration of that property. The next time that property is sold, the same inspection should happen again; plus any changes in status should be identified and listed. Then the property owner should have to provide proof that any work done that required a building permit and final inspection sign-off was actually obtained. If it’s a pre 1978 home all required RRP paperwork must be provided as well. If any of this can’t be provided by the seller, the property can’t be sold. And, if such information cannot be provided the entire property must be brought up to current building code standards and be dust wipe tested for lead paint contamination before it can be sold.

How about before any real-estate is sold why not require a comprehensive inspection and inventory of the home be done? By doing so we could document the condition and configuration of that property. The next time that property is sold, the same inspection should happen again; plus any changes in status should be identified and listed. Then the property owner should have to provide proof that any work done that required a building permit and final inspection sign-off was actually obtained. If it’s a pre 1978 home all required RRP paperwork must be provided as well. If any of this can’t be provided by the seller, the property can’t be sold. And, if such information cannot be provided the entire property must be brought up to current building code standards and be dust wipe tested for lead paint contamination before it can be sold.

Building product suppliers who have high debt may not be able to finance the cost of increasing their inventories to keep up with the predicted supply and demand challenges as the economy improves. If this happens at your supplier you may find that many products, even common commodities like framing lumber, will be out of stock. Imagine going to the lumberyard first thing in the morning to get the materials you need to frame a deck or reframe that kitchen, only to find out you can’t get what you need. To keep working that day you might have to pay for longer lengths than you need, or might even have to drive to a different supplier in the hopes that they will have what you need so you can work that day. Remember, if you lose two hours chasing materials, in reality you also lost two hours of productive time on the job. That would mean you lost a total of four hours you could have billed your client for if the materials were already at the jobsite.

Building product suppliers who have high debt may not be able to finance the cost of increasing their inventories to keep up with the predicted supply and demand challenges as the economy improves. If this happens at your supplier you may find that many products, even common commodities like framing lumber, will be out of stock. Imagine going to the lumberyard first thing in the morning to get the materials you need to frame a deck or reframe that kitchen, only to find out you can’t get what you need. To keep working that day you might have to pay for longer lengths than you need, or might even have to drive to a different supplier in the hopes that they will have what you need so you can work that day. Remember, if you lose two hours chasing materials, in reality you also lost two hours of productive time on the job. That would mean you lost a total of four hours you could have billed your client for if the materials were already at the jobsite. Lumber and building materials dealers who cut back on staff may also be challenged to help you sell to your customers. If you had a customer who wanted to see the door, cabinets or windows you recommend, will you be able to send them down to your local supplier to see the products they are looking for? What is the condition of the showroom? Is there going to be anyone there to make and take the time to meet with and help your customer? Will the person working at that dealer have the sales skills, product knowledge and knowledge about you and your business to help you make the sale?

Lumber and building materials dealers who cut back on staff may also be challenged to help you sell to your customers. If you had a customer who wanted to see the door, cabinets or windows you recommend, will you be able to send them down to your local supplier to see the products they are looking for? What is the condition of the showroom? Is there going to be anyone there to make and take the time to meet with and help your customer? Will the person working at that dealer have the sales skills, product knowledge and knowledge about you and your business to help you make the sale?

First, my feeling is that they are not discussions if someone can decide whether or not they want my comment to be part of the discussion. I say this because I have noticed both on LinkedIn and on several different national newspaper sites I visited and commented on the moderator limits the comments to only those that support their own opinions and or to control the direction of the conversation. We live in a free country where our freedom to express our opinions differentiates us from many other countries on this planet. It pains me to see that some are trying to take that freedom away from us to serve their own purposes and or to purposely mislead readers.

First, my feeling is that they are not discussions if someone can decide whether or not they want my comment to be part of the discussion. I say this because I have noticed both on LinkedIn and on several different national newspaper sites I visited and commented on the moderator limits the comments to only those that support their own opinions and or to control the direction of the conversation. We live in a free country where our freedom to express our opinions differentiates us from many other countries on this planet. It pains me to see that some are trying to take that freedom away from us to serve their own purposes and or to purposely mislead readers.

If group members are behaving in an inappropriate and or unprofessional manner, there should be a defined way to have their ability to participate in the current discussion instantly terminated. And, if they have been terminated from a certain number of previous discussions, perhaps they should be permanently removed from the group, maybe even from LinkedIn.

If group members are behaving in an inappropriate and or unprofessional manner, there should be a defined way to have their ability to participate in the current discussion instantly terminated. And, if they have been terminated from a certain number of previous discussions, perhaps they should be permanently removed from the group, maybe even from LinkedIn. I hope those of you reading this see my purpose in writing this as a genuine attempt to protect the value we get and enjoy from productive and professional discussions at social media sites and online discussions. To protect and facilitate discussions where all members can openly share advice and opinions without the risk of attacks and being subjected to foul language. As one frustrated commenter put it, LinkedIn should be a place where we can safely ask questions and as true professionals safely help each other improve our businesses and our lives. If you have a suggestion to help accomplish this, I hope you will add it to the list I offered above.

I hope those of you reading this see my purpose in writing this as a genuine attempt to protect the value we get and enjoy from productive and professional discussions at social media sites and online discussions. To protect and facilitate discussions where all members can openly share advice and opinions without the risk of attacks and being subjected to foul language. As one frustrated commenter put it, LinkedIn should be a place where we can safely ask questions and as true professionals safely help each other improve our businesses and our lives. If you have a suggestion to help accomplish this, I hope you will add it to the list I offered above. If you agree something must be done about this concern please make others aware of this blog post so they can speak their views as well. Although I will post this blog to LinkedIn discussion groups, I cannot know for sure or control whether they are being moderated or not. If you find this article via LinkedIn, rather than post your comment on LinkedIn, post it here. I promise I won’t moderate the comments you leave here at my blog, every comment will be posted right away. I have and will however delete inappropriate comments and or comments with foul language.

If you agree something must be done about this concern please make others aware of this blog post so they can speak their views as well. Although I will post this blog to LinkedIn discussion groups, I cannot know for sure or control whether they are being moderated or not. If you find this article via LinkedIn, rather than post your comment on LinkedIn, post it here. I promise I won’t moderate the comments you leave here at my blog, every comment will be posted right away. I have and will however delete inappropriate comments and or comments with foul language.