More Work Coming In Than You Can Produce? – Here’s Some Guidance and Advice

The Joint Center for Housing Studies at Harvard University indicates that the dollars spent on remodeling will increase by 8.6% by the end of 2016. Most remodelers are already feeling this surge in spending as their backlog of work keeps increasing and at the same time the number of estimates they need to push out is also increasing. Smart business owners seeing this happening are already increasing their field staff capacity to take advantage of the work. Adding staff can help get more work done. However if production efficiency and organization are challenged due to the growth profits can quickly drop. To help these contractors out I have searched out and assembled the list of articles below. Each article is helpful, but collectively they can help identify a plan of action contractors can take to protect the profits they expect to earn by growing their businesses.

The Joint Center for Housing Studies at Harvard University indicates that the dollars spent on remodeling will increase by 8.6% by the end of 2016. Most remodelers are already feeling this surge in spending as their backlog of work keeps increasing and at the same time the number of estimates they need to push out is also increasing. Smart business owners seeing this happening are already increasing their field staff capacity to take advantage of the work. Adding staff can help get more work done. However if production efficiency and organization are challenged due to the growth profits can quickly drop. To help these contractors out I have searched out and assembled the list of articles below. Each article is helpful, but collectively they can help identify a plan of action contractors can take to protect the profits they expect to earn by growing their businesses.

A good number of contractors have been contacting me for help in this area. Most share now that they have more staff they are challenged to properly manage them and the sequence of work. Others report they have come to realize they may have hired the wrong staff. The solutions to these problems are actually not that difficult to put in place. What typically gets in the way is not knowing what systems to put in place to support the growth and how to get things started.

Here is one message I got just today, from an employee:

“Hello. I was hired 3 years ago as an estimator. We had 2 carpenters and a super. We now have grown into 7 carpenters, super, production manager and additional secretary. None of our carpenters are "lead carpenters" but about 4 think they are. We are experiencing some growing pains for sure so any input would help. Thanks.”

So, here is my list of helpful articles for contractors seeking to advance and grow their production capabilities. The articles will help enlighten you to what your options are as well as several important considerations to be aware of before you jump in and get things started. I hope you find the info helpful and motivating.

So, here is my list of helpful articles for contractors seeking to advance and grow their production capabilities. The articles will help enlighten you to what your options are as well as several important considerations to be aware of before you jump in and get things started. I hope you find the info helpful and motivating.

List of articles about growing production capacity at a Remodeling Company:

Options for Managing Production

What’s the Difference Between a Production Manager and a Production Supervisor?

All I want for Christmas… Is a Real Production Manager!

Is He Really a Lead Carpenter?

Key Differences Between Carpenters and Great Lead Carpenters: Part 1

Key Differences Between Carpenters and Great Lead Carpenters: Part 2

Checklist for Implementing the Lead Carpenter System

Considerations for Putting the Right Employee on the Right Job

Help With Evolving From Contractor to Construction Business Owner

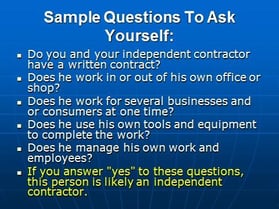

The government has recently been cracking down on improper classification of workers as subcontractors. Understanding the difference, at least in the eyes of the government, can help a remodeler avoid challenges as well as the fines and penalties that come with misclassification. I recently became aware of an additional consideration as a result of reading an article in Remodeling magazine titled

The government has recently been cracking down on improper classification of workers as subcontractors. Understanding the difference, at least in the eyes of the government, can help a remodeler avoid challenges as well as the fines and penalties that come with misclassification. I recently became aware of an additional consideration as a result of reading an article in Remodeling magazine titled  When a customer experiences what Perry speaks to its not likely the contractor performing the work will ever get future business or referrals from the disappointed customer. Remember, quality is not just determined by the final outcome. Quality is also determined by the experience the consumer has as the product is being delivered.

When a customer experiences what Perry speaks to its not likely the contractor performing the work will ever get future business or referrals from the disappointed customer. Remember, quality is not just determined by the final outcome. Quality is also determined by the experience the consumer has as the product is being delivered.

language of the subs you work with which details the scope of work they are to perform independently, you and or your business will be forced to orally direct the work of the subs. Once you do that the government no longer classifies them as subs, but rather as employees. That is therefore misclassification. According to an article at workcompcentral, in Tennessee a company by the name of Aguilar Carpentry was caught misclassifying workers and was fined $73,000. In another article posted to WTNH.com a CT contractor was fined $20,240 for misclassification. Those fine amounts would put most remodelers out of business.

language of the subs you work with which details the scope of work they are to perform independently, you and or your business will be forced to orally direct the work of the subs. Once you do that the government no longer classifies them as subs, but rather as employees. That is therefore misclassification. According to an article at workcompcentral, in Tennessee a company by the name of Aguilar Carpentry was caught misclassifying workers and was fined $73,000. In another article posted to WTNH.com a CT contractor was fined $20,240 for misclassification. Those fine amounts would put most remodelers out of business.

The majority of remodeling contractors who participate in the remodeling industry are holding the industry back from becoming much more professional and successful. Remodelers forever complain about what they perceive the government and even consumers do to them to make running a business and earning a profit difficult. However in many ways remodelers are their own worse enemies, creating problems for themselves and the industry by both their actions as well as their lack of action. Below are just five things I wish all remodelers and the industry would change, but won’t.

The majority of remodeling contractors who participate in the remodeling industry are holding the industry back from becoming much more professional and successful. Remodelers forever complain about what they perceive the government and even consumers do to them to make running a business and earning a profit difficult. However in many ways remodelers are their own worse enemies, creating problems for themselves and the industry by both their actions as well as their lack of action. Below are just five things I wish all remodelers and the industry would change, but won’t.

There are probably more than one million remodeling businesses in the United States if you include those without payroll. Sadly, I bet fewer than 20% operate completely legal. That’s probably why so many remodelers find some way to rationalize why they tolerate other illegal businesses; “People who live in glass houses shouldn’t throw stones”. Here is just a partial checklist you can use to self-assess: RRP, OSHA, permits, using 1099 workers, taking cash, proper licensing… Need I go on?

There are probably more than one million remodeling businesses in the United States if you include those without payroll. Sadly, I bet fewer than 20% operate completely legal. That’s probably why so many remodelers find some way to rationalize why they tolerate other illegal businesses; “People who live in glass houses shouldn’t throw stones”. Here is just a partial checklist you can use to self-assess: RRP, OSHA, permits, using 1099 workers, taking cash, proper licensing… Need I go on?  Many contractors are using what are refer to as 1099 workers to avoid employee and payroll related administrative responsibilities and financial costs. Some use this tactic to reduce their costs to help win bids and or make more money. If you never get caught you may feel or believe it was worth it. On the other hand if you get caught, whether you knew what you were doing was illegal or you really believed what you were doing was OK, the financial and litigation related costs can kill your business. The chance of this happening has dramatically increased in certain areas of the country because Washington is offering money to states to help them do so. Read on to find out about what is already happening in Virginia.

Many contractors are using what are refer to as 1099 workers to avoid employee and payroll related administrative responsibilities and financial costs. Some use this tactic to reduce their costs to help win bids and or make more money. If you never get caught you may feel or believe it was worth it. On the other hand if you get caught, whether you knew what you were doing was illegal or you really believed what you were doing was OK, the financial and litigation related costs can kill your business. The chance of this happening has dramatically increased in certain areas of the country because Washington is offering money to states to help them do so. Read on to find out about what is already happening in Virginia. That means you have to pay up on any fines, at their full rate (anywhere from $7K to 70K per violation) right away. Then you have to decide if you are willing to wait for your legal case to make it through a legal system sponsored by the same entity that is accusing your business.

That means you have to pay up on any fines, at their full rate (anywhere from $7K to 70K per violation) right away. Then you have to decide if you are willing to wait for your legal case to make it through a legal system sponsored by the same entity that is accusing your business.

On April 2nd, 2015 I presented a half day marketing workshop titled "Choosing and Targeting the Right Customers and Projects Types for Your Business". The workshop was billed as the keynote session for the

On April 2nd, 2015 I presented a half day marketing workshop titled "Choosing and Targeting the Right Customers and Projects Types for Your Business". The workshop was billed as the keynote session for the  Take advantage of the timing

Take advantage of the timing  Stop taking just any customers and jobs. Be selective about who you will let become your customers. For example why not only work with people who would say they are "working with" you, not those who would say you are "working for them". Also, be selective about the project types you go after. For example why not attract people who want high quality products. If you sell using one markup across all cost categories the gross profit dollars earned on material intensive projects due to higher price point products is an easier way to meet overhead and net profit goals, both now and in the future, particularly when compared to selling and producing labor intensive projects.

Stop taking just any customers and jobs. Be selective about who you will let become your customers. For example why not only work with people who would say they are "working with" you, not those who would say you are "working for them". Also, be selective about the project types you go after. For example why not attract people who want high quality products. If you sell using one markup across all cost categories the gross profit dollars earned on material intensive projects due to higher price point products is an easier way to meet overhead and net profit goals, both now and in the future, particularly when compared to selling and producing labor intensive projects. The old traditional marketing methods of trying to find prospects who want your services now and interrupting them to get their attention no longer work. Today consumers are the ones deciding how they will find and qualify their project ideas as well as the contractor they will work with. Instead use inbound marketing tactics that help consumers find your business. This should be one of the two primary purposes of your marketing and can be accomplished on your web site using SEO tactics and good content on your site’s pages as well as your blog. The other primary purpose of your marketing, particularly at your web site, should be to help prospects decide if what you offer and how you do business are right for them. In other words your marketing should help them prequalify themselves so they either want to contact you or know they shouldn't.

The old traditional marketing methods of trying to find prospects who want your services now and interrupting them to get their attention no longer work. Today consumers are the ones deciding how they will find and qualify their project ideas as well as the contractor they will work with. Instead use inbound marketing tactics that help consumers find your business. This should be one of the two primary purposes of your marketing and can be accomplished on your web site using SEO tactics and good content on your site’s pages as well as your blog. The other primary purpose of your marketing, particularly at your web site, should be to help prospects decide if what you offer and how you do business are right for them. In other words your marketing should help them prequalify themselves so they either want to contact you or know they shouldn't.

I often hear contractors say they offer fair pricing. When I ask them what they mean by that most really can't provide a logical answer, or their answer is subjective. It got me to thinking about what fair pricing really is. I came up with three considerations I think make a contractor's pricing fair to their customers, but also to their business as well as their employees. Let me know what you think.

I often hear contractors say they offer fair pricing. When I ask them what they mean by that most really can't provide a logical answer, or their answer is subjective. It got me to thinking about what fair pricing really is. I came up with three considerations I think make a contractor's pricing fair to their customers, but also to their business as well as their employees. Let me know what you think. I would suspect most contractors work for customers who have good jobs offering decent pay for the job performed, workers compensation coverage, benefits like vacation and holiday pay so they can enjoy life, health insurance so they can stay healthy and retirement contributions so they can save for a comfortable retirement. I bet if their employers took any of those things away from them “it wouldn’t be fair”.

I would suspect most contractors work for customers who have good jobs offering decent pay for the job performed, workers compensation coverage, benefits like vacation and holiday pay so they can enjoy life, health insurance so they can stay healthy and retirement contributions so they can save for a comfortable retirement. I bet if their employers took any of those things away from them “it wouldn’t be fair”.

In the design industry we have many challenges besides meeting the concerns, wants, and needs of our precious clients. Many businesses have resorted to marketing on the basis of something for free. It prompts clients to want what is offered for free, however, at the same time, causes the knee jerk reaction question to arise, “How can it be free, what’s the catch”?

This poses itself as one of the challenges most noteworthy; the honest perception of value that is created. For a certainty, most trends are to downplay, for market segmenting purposes, the true value of reputable trades or product.

In the design industry we have many challenges besides meeting the concerns, wants, and needs of our precious clients. Many businesses have resorted to marketing on the basis of something for free. It prompts clients to want what is offered for free, however, at the same time, causes the knee jerk reaction question to arise, “How can it be free, what’s the catch”?

This poses itself as one of the challenges most noteworthy; the honest perception of value that is created. For a certainty, most trends are to downplay, for market segmenting purposes, the true value of reputable trades or product.  To advertise something for “free” in reality means something else needs to recoup the costs related to the “free” product or service. This is, in all respects, “Bait and Switch” by offering something for free that really isn’t. Doing so may call into question being honest in our business dealings.

To advertise something for “free” in reality means something else needs to recoup the costs related to the “free” product or service. This is, in all respects, “Bait and Switch” by offering something for free that really isn’t. Doing so may call into question being honest in our business dealings. Lowest cost marketing is not being honest in business dealings, as it may not spell out the true reason something is less, or much less, as many products and services, on the surface, appear to be the same. The adage, “You Get What You Pay For”, is usually visited after the disappointment comes, once the bargain fails to meet the expectation and the delight for the savings is replaced by the sinking feeling, “I’ve been had again”. As designers, is this really the outcome we want our clients to experience, let alone, having to deal with it once exposed?

Lowest cost marketing is not being honest in business dealings, as it may not spell out the true reason something is less, or much less, as many products and services, on the surface, appear to be the same. The adage, “You Get What You Pay For”, is usually visited after the disappointment comes, once the bargain fails to meet the expectation and the delight for the savings is replaced by the sinking feeling, “I’ve been had again”. As designers, is this really the outcome we want our clients to experience, let alone, having to deal with it once exposed?

It would appear to anyone who knows and understands how lumber is graded and sold that the state of California is looking for ways to fine legitimate businesses, even if those businesses are conducting business using traditional and industry accepted methods and terminology.

It would appear to anyone who knows and understands how lumber is graded and sold that the state of California is looking for ways to fine legitimate businesses, even if those businesses are conducting business using traditional and industry accepted methods and terminology.  Will you have to describe the actual dimensions of every framing product you specify in your next proposal, including the actual thickness of sheet goods?

Will you have to describe the actual dimensions of every framing product you specify in your next proposal, including the actual thickness of sheet goods?

Be the leader you need to be. Work on your leadership skills and make sure you understand the difference between leadership and management, and when to use one versus the other. Good employees want to be lead, not supervised.

Be the leader you need to be. Work on your leadership skills and make sure you understand the difference between leadership and management, and when to use one versus the other. Good employees want to be lead, not supervised. Know your limits. Do what you can yourself but get the professional help you need to do things right; to avoid costly mistakes, increase the likelihood of success and maximize the results for your all your efforts.

Know your limits. Do what you can yourself but get the professional help you need to do things right; to avoid costly mistakes, increase the likelihood of success and maximize the results for your all your efforts.

Second is that the supply chain is finally spending money again on marketing to and investing in their remodeling contractor customers. Although still not as busy as they used to be, trade shows this past year have grow in size again as more manufacturers and distributors are back participating at the shows. Also, since about early this past summer, the number of manufacturers, distributors, dealers and trade associations contacting me about speaking at their events has also dramatically picked up. The supply chain is once again spending money to educate their staff as well as their contractor customers, as a way to grow their businesses as well as their customers’.

Second is that the supply chain is finally spending money again on marketing to and investing in their remodeling contractor customers. Although still not as busy as they used to be, trade shows this past year have grow in size again as more manufacturers and distributors are back participating at the shows. Also, since about early this past summer, the number of manufacturers, distributors, dealers and trade associations contacting me about speaking at their events has also dramatically picked up. The supply chain is once again spending money to educate their staff as well as their contractor customers, as a way to grow their businesses as well as their customers’.

think sums things up

think sums things up