Compliance Checklist: Will You Be Ready If OSHA Visits Your Job Site?

Recently there has been a lot of buzz around the remodeling and home improvement industries regarding OSHA enforcement. OSHA has definitely stepped up its focus on residential construction. With the onset of summer weather much more work is being done outside making it easier for OSHA Inspectors to observe not only where work is happening but also easily observe and identify violations by only having to drive by construction sites. Inspectors have been instructed; if you see it - make a visit. One contractor even reported that an OSHA Inspector was driving around Cambridge MA on a bicycle!

Recently there has been a lot of buzz around the remodeling and home improvement industries regarding OSHA enforcement. OSHA has definitely stepped up its focus on residential construction. With the onset of summer weather much more work is being done outside making it easier for OSHA Inspectors to observe not only where work is happening but also easily observe and identify violations by only having to drive by construction sites. Inspectors have been instructed; if you see it - make a visit. One contractor even reported that an OSHA Inspector was driving around Cambridge MA on a bicycle!

OSHA requirements are not new, even though you might think so by reading some of the banter on sites like LinkedIn. Significant OSHA enforcement within the residential construction industry has only recently been happening and has been getting a lot of press coverage. As a result many contractors are only just now becoming aware that OSHA compliance and the related expenses to comply apply to them.

When Does OSHA Apply?

OSHA requirements do not apply if you are the business owner and only work alone. However, OSHA requirements do apply when employees or other workers conduct work activities at your jobsite. So, if you are a general contractor, OSHA will hold you responsible for verifying OSHA compliance and overseeing the actions of your subcontractors while at your jobsites.

OSHA requirements do not apply if you are the business owner and only work alone. However, OSHA requirements do apply when employees or other workers conduct work activities at your jobsite. So, if you are a general contractor, OSHA will hold you responsible for verifying OSHA compliance and overseeing the actions of your subcontractors while at your jobsites.

Depending on the type of work you perform, specific OSHA compliance requirements will vary. To simplify what you need to consider, just assume that no matter what they are doing, your business is responsible to protect the health and safety of all workers at your jobsite. To protect your business and your employees, I suggest OSHA compliance oversight should be included in the job descriptions for lead carpenters, production managers and project managers.

Be Sure To Document Worker Training

Below is short a list of things contractors should consider if they want to be ready when an OSHA Inspector drives by and or stops in to check out your job site. This list comes from Mark Paskell of The Contractors Coaching Partnership. Mark helps contractors and their employees comply with OSHA. He offers group training classes as well as company specific training and assistance with compliance requirements including jobsite practices and the gamut of required documentation. When I spoke to Mark about this topic he stressed that OSHA was concentrating heavily on worker training and protection from fall hazards, and that contractors needed to have written documentation of the training they provide.

Below is short a list of things contractors should consider if they want to be ready when an OSHA Inspector drives by and or stops in to check out your job site. This list comes from Mark Paskell of The Contractors Coaching Partnership. Mark helps contractors and their employees comply with OSHA. He offers group training classes as well as company specific training and assistance with compliance requirements including jobsite practices and the gamut of required documentation. When I spoke to Mark about this topic he stressed that OSHA was concentrating heavily on worker training and protection from fall hazards, and that contractors needed to have written documentation of the training they provide.

OSHA Compliance Checklist for Contractors:

- Keep your job site in a clean an orderly manner

- If on roofs above a 4 pitch use anchor points, harnesses and lifelines

- If you do not use harnesses use guard rails

- When setting ladders make sure they are 3 feet above the roof edge and on stable ground

- Don't use ladder jacks with ladders over 20 feet

- If you use ladder jacks over 10 feet makes sure you are tied off from above

- Wear hard hats and safety goggles

- Make sure scaffolding is set properly with planking

- Set ladders at the right angle

- Don't climb scaffolding bracing

- Don't use the top steps of your step ladders

- Use ladders and step ladders only within the manufacturer's parameters

- Use guard rails on pump staging and do not forget the ends

- Cover skylights in the work area

- Always us guard rails on landings, stairs and ramps

- Use guard rails across large openings on upper levels

- Don't set ladders or staging within 10 feet of power lines

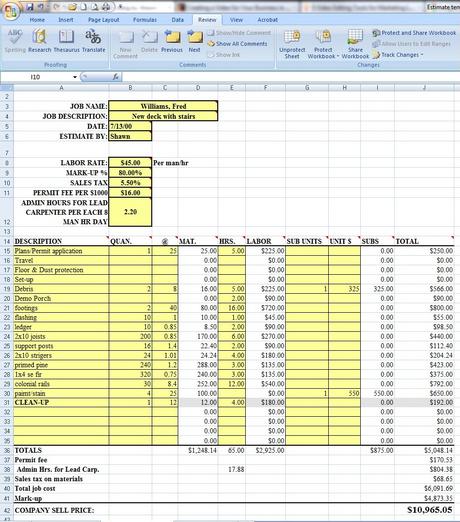

Knowing what to charge clients for the work you do is often the difference between long term success and eventual failure for the business. Many contractors look at estimating simply as a way to determine the cost of a project. In the traditional design-bid model of project delivery, this simplistic approach may work, assuming your sell price generates enough gross profit to cover your overhead and profit requirements. However, if you’re doing design/build, and your current estimating system is limited to only producing the number you charge clients for a project, you may be missing out on many other possible benefits.

Knowing what to charge clients for the work you do is often the difference between long term success and eventual failure for the business. Many contractors look at estimating simply as a way to determine the cost of a project. In the traditional design-bid model of project delivery, this simplistic approach may work, assuming your sell price generates enough gross profit to cover your overhead and profit requirements. However, if you’re doing design/build, and your current estimating system is limited to only producing the number you charge clients for a project, you may be missing out on many other possible benefits. If you think of Design/Build as a way of doing business, your estimating system must become a tool that facilitates how you do business, not just a way to get to the price. Here are several ways a Design/Builder or a remodeler can maximize the potential of the method and system used to do estimating:

If you think of Design/Build as a way of doing business, your estimating system must become a tool that facilitates how you do business, not just a way to get to the price. Here are several ways a Design/Builder or a remodeler can maximize the potential of the method and system used to do estimating:

A long time ago a remodeler in my NARI Chapter who was just starting his business asked me for advice about how he too could have a successful and profitable business. Seeking to keep my response simple and to the point I came up with a list of nine steps. When I was explaining my list to him he asked where he would find the time to do all these things. He said he was already straight out trying to sell and complete work. That’s when I added step number one to the ten step list below.

A long time ago a remodeler in my NARI Chapter who was just starting his business asked me for advice about how he too could have a successful and profitable business. Seeking to keep my response simple and to the point I came up with a list of nine steps. When I was explaining my list to him he asked where he would find the time to do all these things. He said he was already straight out trying to sell and complete work. That’s when I added step number one to the ten step list below.  Recharge Your Batteries!

Recharge Your Batteries!

Paying the bills for yesterday’s project using the deposit money from a job you haven’t started yet may seem to solve the cash flow problem; however it only temporarily puts off the eventual reality that you are buying jobs instead of selling them. Due to the recession many contractors discovered this reality when the new job deposits dried up and there was no money in the bank to pay the bills for work already completed.

Paying the bills for yesterday’s project using the deposit money from a job you haven’t started yet may seem to solve the cash flow problem; however it only temporarily puts off the eventual reality that you are buying jobs instead of selling them. Due to the recession many contractors discovered this reality when the new job deposits dried up and there was no money in the bank to pay the bills for work already completed.