Is EPA Not Listening Or In Denial About The Effects of RRP Rule?

Remodelers across the country have been complaining about the additional costs related to the EPA RRP rule. As predicted by many trade groups and individual commenters during the comment period before the rule was promulgated, the additional costs to comply with the rule have created a significant pricing divide between those businesses complying with the rule and those that are not. As a result, and again as predicted by many commenters, this has lead to an increase in illegally performed renovations, as consumers, motivated by price, are ignoring the dangers of lead paint and opt to hire contractors who are not abiding by the rule. Under the rule, a renovator can be fined up to $37,500 for willful and knowing violations of the rule, and can even face jail time. Unfortunately, there is no legal consequence to a homeowner for hiring an illegally operating firm, even if the consumer is aware of the rule and its requirements.

Facts show that the EPA has, for the most part, ignored predictions, insight and feedback from the regulated community; both during the comment period before the rule was promulgated and since the rule took effect on April 22, 2010.

Here is an excerpt from the preamble of the final rule that demonstrates EPA’s disregard for the concerns of the businesses regulated by the RRP Rule:

“It is difficult to determine with any amount of certainty whether this final rule will have unintended consequences. However, EPA agrees that it is important to minimize disincentives for using certified renovation firms who follow the work practices required by this rule. EPA also agrees that practicality is an important consideration. Given the relatively low estimated overall average per-job cost of this final rule, which is $35, and the relatively easy-to-use work practices required by this final rule, EPA does not expect the incremental costs associated with this rule to be a determinative factor for consumers. However, that relatively low cost has resulted in part from EPA's efforts to contain the costs of this rule in order to avoid creating disincentives to using certified renovation firms, and EPA has viewed the comments received with those considerations in mind.”

It would seem from reading the above text that EPA did not listen to the many commenters who sited additional costs well beyond EPA’s estimated average additional cost of $35.00. The text also shows that the EPA rationalized that consumers would not be inclined to avoid working with a certified firm based on such a small price difference. Was their math wrong? Are they oblivious to the real costs reported by those doing the work now that the rule is in place? Have they done any research to determine if the rule has had any unintended consequences? Or, are they willfully ignoring the true realities and effects of the additional costs to comply?

It would seem from reading the above text that EPA did not listen to the many commenters who sited additional costs well beyond EPA’s estimated average additional cost of $35.00. The text also shows that the EPA rationalized that consumers would not be inclined to avoid working with a certified firm based on such a small price difference. Was their math wrong? Are they oblivious to the real costs reported by those doing the work now that the rule is in place? Have they done any research to determine if the rule has had any unintended consequences? Or, are they willfully ignoring the true realities and effects of the additional costs to comply?

In a recent article from NWTN Today, published on December 31, 2010, Steve Owens, Assistant Administrator of the Office of Prevention, Pesticides and Toxic Substances at the EPA offered the following. It certainly proves that despite evidence to the contrary, EPA is still not listening to the regulated community or is still in denial:

“Getting lead-safe certified is it the right thing to do for contractors, their customers, and their employees, and especially for the children who spend time near spaces that are being renovated,” said Owens. Owens says that the EPA is mindful of the small added costs that may result from complying with this important rule. To that end, he said the EPA is launching a consumer campaign designed to raise awareness of the dangers of lead paint poisoning, and encourage consumers to choose only contractors who are Lead-Safe Certified"

Don’t get me going about the “Small added costs” and that the EPA plans to “encourage” consumers to choose only contractors who are Lead-Safe Certified. Wouldn’t it have made sense and have helped those businesses complying with the rule to have done the outreach and education before and as the rule went into effect? Wouldn’t have made sense to “require” consumers choose only contractors who are Lead-Safe Certified?

Don’t get me going about the “Small added costs” and that the EPA plans to “encourage” consumers to choose only contractors who are Lead-Safe Certified. Wouldn’t it have made sense and have helped those businesses complying with the rule to have done the outreach and education before and as the rule went into effect? Wouldn’t have made sense to “require” consumers choose only contractors who are Lead-Safe Certified?

Looking for accurate information about the EPA RRP rule?

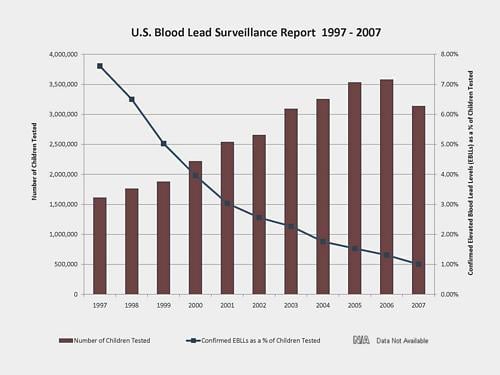

Looking for accurate information about the EPA RRP rule?  How bad is the child lead poisoning problem? And, how many of the poisoned children were poisoned by lead due to renovation work? The answer to these two simple questions might surprise you. Had the EPA and Congress done adequate research, might they have found better and more cost effective ways to further reduce the number of lead poisoned children?

How bad is the child lead poisoning problem? And, how many of the poisoned children were poisoned by lead due to renovation work? The answer to these two simple questions might surprise you. Had the EPA and Congress done adequate research, might they have found better and more cost effective ways to further reduce the number of lead poisoned children?

No child should be poisoned by lead. However, our government and politicians are concentrating in the wrong area if they really want to substantially address the lead poisoning problem. As I had discussed in a

No child should be poisoned by lead. However, our government and politicians are concentrating in the wrong area if they really want to substantially address the lead poisoning problem. As I had discussed in a

Yesterday

Yesterday  In my opinion, the ability to work with and interact with the same people who not only enforce the rule in MA, but also have the ability to help shape the MA RRP rule, has been a major plus for those Massachusetts contractors affected by the rule. At the budget hearing I shared this opinion and stressed that I hoped DOS would get adequate budgeting to keep such communication opportunities available in the future. Here are a few of the items I suggested at the hearing:

In my opinion, the ability to work with and interact with the same people who not only enforce the rule in MA, but also have the ability to help shape the MA RRP rule, has been a major plus for those Massachusetts contractors affected by the rule. At the budget hearing I shared this opinion and stressed that I hoped DOS would get adequate budgeting to keep such communication opportunities available in the future. Here are a few of the items I suggested at the hearing:

The recent RRP rule requires contractors to follow certain lead-safe work practices to protect homeowners, their families and the workers who perform work where lead paint is or might be present. The rule also requires training of workers to be sure they know how to do the work, protect themselves and stay in compliance with the rule. Lead poisoning is a real issue. Protecting people from the dangers of lead is the right thing to do. Although we may all have our own opinions about the actual rule itself, as an industry and as professionals, we must do what is right.

The recent RRP rule requires contractors to follow certain lead-safe work practices to protect homeowners, their families and the workers who perform work where lead paint is or might be present. The rule also requires training of workers to be sure they know how to do the work, protect themselves and stay in compliance with the rule. Lead poisoning is a real issue. Protecting people from the dangers of lead is the right thing to do. Although we may all have our own opinions about the actual rule itself, as an industry and as professionals, we must do what is right. Many businesses, ranging from remodelers, subcontractors, manufacturers, distributors, vendors, trainers and even trade associations have contacted me to express their disappointment with EPA’s handling of this rule since it took effect on April 22, 2010. Although EPA claims to have done extensive outreach to consumers and the regulated community, the results of their efforts have proven to be ineffective. Enforcement of the rule so far has been almost non-existent, particularly in light of the number of non-compliant businesses still doing the work in ways that are definitely poisoning our children, their families and those workers who perform renovations where lead is present. The EPA’s June announcement regarding their decision to delay enforcement of the training and firm certification requirements was interpreted by many renovators as a delay of the whole rule, not just the fines for such violations. As a result, many businesses trying to support renovators in complying with the rule have reported that sales have dropped to the point where they must consider shutting down. I could go on with my list but I am probably preaching to the choir.

Many businesses, ranging from remodelers, subcontractors, manufacturers, distributors, vendors, trainers and even trade associations have contacted me to express their disappointment with EPA’s handling of this rule since it took effect on April 22, 2010. Although EPA claims to have done extensive outreach to consumers and the regulated community, the results of their efforts have proven to be ineffective. Enforcement of the rule so far has been almost non-existent, particularly in light of the number of non-compliant businesses still doing the work in ways that are definitely poisoning our children, their families and those workers who perform renovations where lead is present. The EPA’s June announcement regarding their decision to delay enforcement of the training and firm certification requirements was interpreted by many renovators as a delay of the whole rule, not just the fines for such violations. As a result, many businesses trying to support renovators in complying with the rule have reported that sales have dropped to the point where they must consider shutting down. I could go on with my list but I am probably preaching to the choir. Second, if you have suggestions, contacts and or the means to assist me in distributing this information to those who can help us with this important issue, please let me know. Anyone is welcome to leave comments here at the end of this blog. However, I would prefer that you e-mail me your thoughts in letter-like form and that you include your complete contact information as well as your permission to use and distribute what you send me. I will not redistribute information from anonymous parties.

Second, if you have suggestions, contacts and or the means to assist me in distributing this information to those who can help us with this important issue, please let me know. Anyone is welcome to leave comments here at the end of this blog. However, I would prefer that you e-mail me your thoughts in letter-like form and that you include your complete contact information as well as your permission to use and distribute what you send me. I will not redistribute information from anonymous parties. While at the workshop I found one thing the main instructor Darcy Cook of Safety Trainers said to be very important for contractors to be aware of. Under the OSHA Lead in Construction Standard, contractors must assume their employees will be exposed to lead above OSHA’s established action level requiring the use of respirators until they actually conduct air monitoring testing to prove otherwise.

While at the workshop I found one thing the main instructor Darcy Cook of Safety Trainers said to be very important for contractors to be aware of. Under the OSHA Lead in Construction Standard, contractors must assume their employees will be exposed to lead above OSHA’s established action level requiring the use of respirators until they actually conduct air monitoring testing to prove otherwise.

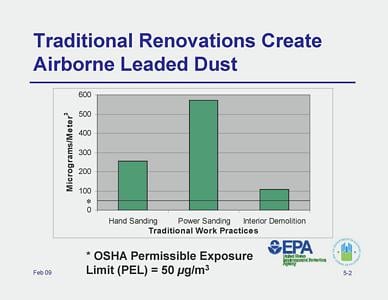

So, under OSHA requirements, before allowing them to do RRP related work or even enter a contained work area, employees must first be sent to a physician to be sure they are healthy enough to wear a respirator. Then they must be fit tested by a professional and provided with a properly fitted respirator that protects them from worst case lead exposure scenarios based on the kind of work they do. They must also be trained how to select, use, clean and store a respirator. And, they must wear the respirator until the air monitoring testing is done to identify when a respirator is required and when it is not depending on how the work is performed and what engineering controls are being used.

So, under OSHA requirements, before allowing them to do RRP related work or even enter a contained work area, employees must first be sent to a physician to be sure they are healthy enough to wear a respirator. Then they must be fit tested by a professional and provided with a properly fitted respirator that protects them from worst case lead exposure scenarios based on the kind of work they do. They must also be trained how to select, use, clean and store a respirator. And, they must wear the respirator until the air monitoring testing is done to identify when a respirator is required and when it is not depending on how the work is performed and what engineering controls are being used. Renovators should be aware that in addition to EPA or administering states, other individuals or entities may likely take advantage of the documentation requirements to hold renovators accountable for their actions or lack thereof.

Renovators should be aware that in addition to EPA or administering states, other individuals or entities may likely take advantage of the documentation requirements to hold renovators accountable for their actions or lack thereof. OSHA could use RRP paperwork to prove non-compliance with its Lead in Construction Standards. OSHA’s worker protection requirements related to lead are very specific. Information contained in the required RRP documentation, particularly the renovation checklist and non-certified worker training documentation, could easily be used to show workers were not adequately trained and or protected when working in contained work areas. A lack of the required documentation could also be used by OSHA to demonstrate negligence by the business.

OSHA could use RRP paperwork to prove non-compliance with its Lead in Construction Standards. OSHA’s worker protection requirements related to lead are very specific. Information contained in the required RRP documentation, particularly the renovation checklist and non-certified worker training documentation, could easily be used to show workers were not adequately trained and or protected when working in contained work areas. A lack of the required documentation could also be used by OSHA to demonstrate negligence by the business.  The Commonwealth of MA Executive Office of Labor and Workforce Development will be holding public hearings where interested parties can attend to provide suggestions to Joanne F. Goldstein, the Secretary of Labor and Workforce Development, regarding how the money appropriated to the Department of Labor (DOL) and the Division of Occupational Safety (DOS) should be spent in Fiscal Year 2012.

The Commonwealth of MA Executive Office of Labor and Workforce Development will be holding public hearings where interested parties can attend to provide suggestions to Joanne F. Goldstein, the Secretary of Labor and Workforce Development, regarding how the money appropriated to the Department of Labor (DOL) and the Division of Occupational Safety (DOS) should be spent in Fiscal Year 2012. Proper and effective administration and enforcement of the RRP rule will take money. Because the amount of money the DOS and DOL will get in 2012 is already decided, contractors must voice their opinion as to how they think the money should be spent. It is my opinion that the money could actually be invested in the health and safety of Massachusetts citizens to protect them from the dangers associated with contractors who ignore lead-safe work practices. And, if properly and adequately enforced, the RRP rule would not only help to eliminate the underground construction economy here in Massachusetts, it would also help bring in additional revenue for the state in fees to those who get licensed to do the work, in fines to those who operate illegally and in taxes collected if all construction businesses doing RRP work have to pay their equal share of payroll and income taxes.

Proper and effective administration and enforcement of the RRP rule will take money. Because the amount of money the DOS and DOL will get in 2012 is already decided, contractors must voice their opinion as to how they think the money should be spent. It is my opinion that the money could actually be invested in the health and safety of Massachusetts citizens to protect them from the dangers associated with contractors who ignore lead-safe work practices. And, if properly and adequately enforced, the RRP rule would not only help to eliminate the underground construction economy here in Massachusetts, it would also help bring in additional revenue for the state in fees to those who get licensed to do the work, in fines to those who operate illegally and in taxes collected if all construction businesses doing RRP work have to pay their equal share of payroll and income taxes.  Being a landlord brings with it many legal responsibilities related to lead paint that, if not followed, can certainly eat away at any potential profits. There are many rules to consider and be aware of, the most common being the

Being a landlord brings with it many legal responsibilities related to lead paint that, if not followed, can certainly eat away at any potential profits. There are many rules to consider and be aware of, the most common being the  When work is done inside their units, tenants must be given an EPA published pamphlet titled “Renovate Right”. The pamphlet explains the dangers of lead and what is required to protect their and their family’s health and safety when work is being done at the property where they live. If work is to be done in common areas, the pamphlet can either be given to tenants, or, notices can be posted telling tenants how they can receive the pamphlet at no cost to them. Tenants must also be given or made aware how they can request a document titled the

When work is done inside their units, tenants must be given an EPA published pamphlet titled “Renovate Right”. The pamphlet explains the dangers of lead and what is required to protect their and their family’s health and safety when work is being done at the property where they live. If work is to be done in common areas, the pamphlet can either be given to tenants, or, notices can be posted telling tenants how they can receive the pamphlet at no cost to them. Tenants must also be given or made aware how they can request a document titled the  If the landlord does his own work on the rental property and or uses his/her own employees to do so, the landlord must also become an EPA Certified RRP firm and only use trained and certified workers to do the work. If you are a landlord doing your own work,

If the landlord does his own work on the rental property and or uses his/her own employees to do so, the landlord must also become an EPA Certified RRP firm and only use trained and certified workers to do the work. If you are a landlord doing your own work,  NOTE: If you are a landlord, realtor or member of a group representing landlords or realtors seeking help and information about the RRP rules, feel free to

NOTE: If you are a landlord, realtor or member of a group representing landlords or realtors seeking help and information about the RRP rules, feel free to  The New Renovation Repair and Painting Rule could likely be a ticking time bomb for many renovators who are ignorant of, intentionally ignoring and or not following all of the many requirements of the rule. The reason I say this is because of the documentation and record keeping requirements of the RRP Rule. Renovators should keep in mind that under the rule the required documentation for each RRP project must be stored and made available for inspection for up to 3 years after the completion of the project. The EPA and or states that have taken over administration and enforcement of the rule won’t be limited to finding active violations of the rule on jobsites. They will also be able to use the required documentation to determine whether renovators were complying with the rule on all projects completed in the three years preceding an inspection. Check out this

The New Renovation Repair and Painting Rule could likely be a ticking time bomb for many renovators who are ignorant of, intentionally ignoring and or not following all of the many requirements of the rule. The reason I say this is because of the documentation and record keeping requirements of the RRP Rule. Renovators should keep in mind that under the rule the required documentation for each RRP project must be stored and made available for inspection for up to 3 years after the completion of the project. The EPA and or states that have taken over administration and enforcement of the rule won’t be limited to finding active violations of the rule on jobsites. They will also be able to use the required documentation to determine whether renovators were complying with the rule on all projects completed in the three years preceding an inspection. Check out this I had a conversation with one remodeler about the serious risks non-compliance can have for a renovator’s business. His opinion was that the risk of being caught was dependent on “how legal” the remodeler is in the way he/she operates the business. My opinion is that being legal is not measured on any kind of graduated scale. You are either operating the business legally or you are not. I think both EPA and OSHA agree with this logic.

I had a conversation with one remodeler about the serious risks non-compliance can have for a renovator’s business. His opinion was that the risk of being caught was dependent on “how legal” the remodeler is in the way he/she operates the business. My opinion is that being legal is not measured on any kind of graduated scale. You are either operating the business legally or you are not. I think both EPA and OSHA agree with this logic.