Costs Of RRP Compliance Challenging Many Businesses and Likely To Go Higher!

Renovators have justified their concerns about the additional costs of complying with the EPA RRP Rule based on two different but interdependent reasons. First is the cost to the business. Businesses that do comply have to pay to become a certified firm, pay training fees for the required certified renovator training, pay the wages of the certified renovator while he/she trains non-certified workers, pay the wages of employees while they attend training, and must purchase all of the tools, related equipment and personal protection equipment needed by workers to do the work. Second, they cite the additional labor and material costs to perform the work.

These additional costs might not be all that burdensome if all contractors doing RRP work shared the same burdens and where able to recover these costs through the selling prices of their jobs. But, the additional costs become an extreme burden for many businesses if and when they are in competition with illegally operating businesses that avoid the additional costs and therefore are offering lower prices to consumers. Many contractors are reporting that the additional costs are putting them out of business.

Ready for some more bad news? The costs of compliance are likely to go up even higher, for complying businesses as well as for consumers.

- First, the proposed dust wipe amendment, if approved, will definitely increase projects costs and will result in delaying when the consumer can get back into the renovated space.

- Second, in addition to the costs related to the dust wipe testing, because contained areas cannot be re-inhabited until the tests show no lead dust, consumers may need to seek alternate living arrangements while waiting for test results to come back from laboratories.

- Third, because of the lack of a cost effective lead test kit that will recognize lead based on the legal definition of lead equal to or in excess of 1.0 mg/cm\2\ or 0.5% by weight, many projects that would not require lead safe practices must still be performed using lead-safe practices.

Here is excerpt from the final rule preamble:

“Number of events and individuals affected: In the first year that all of the rule requirements will be in effect, there will be an estimated 8.4 million renovation, repair, and painting events where lead-safe work practices will be used due to the rule. As a result, there will be approximately 1.4 million children under the age of 6 who will be affected by having their exposure to lead dust minimized due to the rule. There will also be about 5.4 million adults who will be affected. After improved test kits for determining whether a painted surface contains lead-based paint become available (which is assumed in the analysis to occur by the second year of the rule), the number of renovation, repair, and painting events using lead-safe work practices is expected to drop to 4.4 million events per year. No change in the number of exposures avoided due to the rule is expected because the improved test kit will more accurately identify paint without lead, thus reducing the number of events unnecessarily using the required work practices.”

“Number of events and individuals affected: In the first year that all of the rule requirements will be in effect, there will be an estimated 8.4 million renovation, repair, and painting events where lead-safe work practices will be used due to the rule. As a result, there will be approximately 1.4 million children under the age of 6 who will be affected by having their exposure to lead dust minimized due to the rule. There will also be about 5.4 million adults who will be affected. After improved test kits for determining whether a painted surface contains lead-based paint become available (which is assumed in the analysis to occur by the second year of the rule), the number of renovation, repair, and painting events using lead-safe work practices is expected to drop to 4.4 million events per year. No change in the number of exposures avoided due to the rule is expected because the improved test kit will more accurately identify paint without lead, thus reducing the number of events unnecessarily using the required work practices.”

So, because the EPA falsely assumed that the improved test kits would be available by September 2010, 4.4 million RRP projects will bear the additional cost of lead-safe practices that would not be required if the improved test kits were available. That one bad assumption by EPA, based on the bogus and underestimated average additional cost of $35 per project, will result in $140 million in additional costs for projects “unnecessarily using the required work practices”. What do you think about that? What would consumers think about that?

Looking for accurate information about the EPA RRP rule?

Looking for accurate information about the EPA RRP rule?  The RRP rule requires that dust and debris be controlled in the work area while working in homes built prior to 1978 unless all effected components of the renovation are properly tested and lead is not found. You can find information about the legal definition of lead paint and the accuracy of testing methods

The RRP rule requires that dust and debris be controlled in the work area while working in homes built prior to 1978 unless all effected components of the renovation are properly tested and lead is not found. You can find information about the legal definition of lead paint and the accuracy of testing methods  Required containment is similar for all jobs, but jobs that generate more dust and debris may require protection of larger areas. While the Rule does not require vertical containment, such systems may be helpful in limiting the size of the area affected by the work and may reduce the area that must be cleaned at the end of the job. Pre-engineered containment systems (purchased and home-made) are very helpful in cutting time spent on the job erecting containment and are easier to install than hanging plastic sheeting with tape. These systems also allow the contractor to create a sealed room within a room where the dust can be completely contained to a limited and controlled area.

Required containment is similar for all jobs, but jobs that generate more dust and debris may require protection of larger areas. While the Rule does not require vertical containment, such systems may be helpful in limiting the size of the area affected by the work and may reduce the area that must be cleaned at the end of the job. Pre-engineered containment systems (purchased and home-made) are very helpful in cutting time spent on the job erecting containment and are easier to install than hanging plastic sheeting with tape. These systems also allow the contractor to create a sealed room within a room where the dust can be completely contained to a limited and controlled area.  •

•

The

The  One way to think about this might be to relate it to eating fish. The government often says that if you fish in certain bodies of polluted water, you can safely eat up to so many of the fish you catch without any health concerns. If the government says you can eat up to 3 fish a year, how safe would you feel eating even one fish? Using this analogy, how safe might the owner feel having renovations done if there is any lead present at all at their property?

One way to think about this might be to relate it to eating fish. The government often says that if you fish in certain bodies of polluted water, you can safely eat up to so many of the fish you catch without any health concerns. If the government says you can eat up to 3 fish a year, how safe would you feel eating even one fish? Using this analogy, how safe might the owner feel having renovations done if there is any lead present at all at their property?

"The RRP Rule covers renovations, which are defined as modifications of existing structures or portions of structures. The rule does not apply to demolitions of an entire free-standing building or structure.

"The RRP Rule covers renovations, which are defined as modifications of existing structures or portions of structures. The rule does not apply to demolitions of an entire free-standing building or structure.

Note: The final rule does not prohibit or restrict the use of dry hand sanding or dry hand scraping. EPA has concluded that it is not necessary to prohibit or restrict dry hand sanding or dry hand scraping because the containment, cleaning, and cleaning verification requirements of the rule are effective at minimizing exposure to lead-based paint hazards created by renovations and the migration of dust-lead hazards beyond the work area when dry hand sanding or dry hand scraping is employed.

Note: The final rule does not prohibit or restrict the use of dry hand sanding or dry hand scraping. EPA has concluded that it is not necessary to prohibit or restrict dry hand sanding or dry hand scraping because the containment, cleaning, and cleaning verification requirements of the rule are effective at minimizing exposure to lead-based paint hazards created by renovations and the migration of dust-lead hazards beyond the work area when dry hand sanding or dry hand scraping is employed.

First, there are up-front costs including firm certification (required to offer, sell and or be under contract to perform the work) and the cost of Certified Renovator training for those doing and or supervising the actual work. Other up front costs can include tools and equipment needed to perform the work including a HEPA vacuum, cleaning equipment, personal protection equipment for workers, specialized tools and containment related equipment such as products like Zip Walls.

First, there are up-front costs including firm certification (required to offer, sell and or be under contract to perform the work) and the cost of Certified Renovator training for those doing and or supervising the actual work. Other up front costs can include tools and equipment needed to perform the work including a HEPA vacuum, cleaning equipment, personal protection equipment for workers, specialized tools and containment related equipment such as products like Zip Walls.

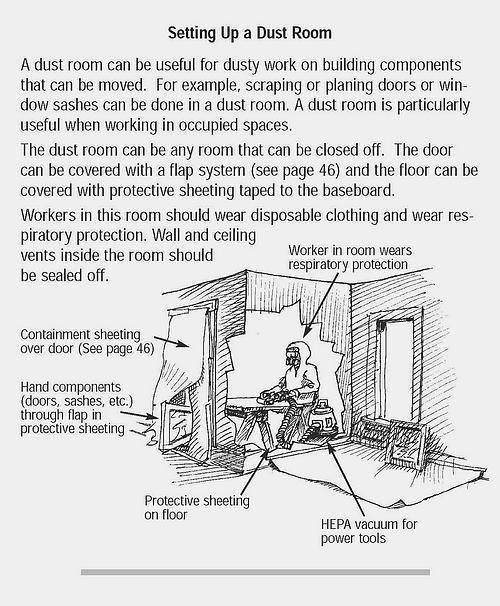

If you are a certified renovator trying to figure out innovative, efficient and time saving production methods to protect profits on EPA RRP related projects you might want to consider a dust room.

If you are a certified renovator trying to figure out innovative, efficient and time saving production methods to protect profits on EPA RRP related projects you might want to consider a dust room.