A Fast, Clean and Safe Way to Remove Lead Paint

One Person’s Opinion: Catherine Brooks, MBA is the owner of a small business, Eco-Strip LLC since 2003. Previous to starting this second business, she owned a consulting practice and worked for 20 years with small private companies, local and state governments, and OSHA. Her specialties were public health, recycling, and executive training. She comes from the Eastern Shore of the Chesapeake Bay. There she learned the hard way that moisture can destroy a paint job. She regrets that she power-washed her older home several years ago and SOON will now have to repaint it.

A Fast, Clean and Safe Way to Remove Lead Paint

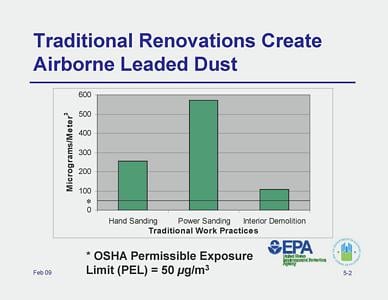

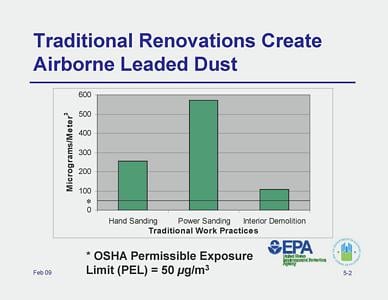

Good painters know that surface preparation before repainting is critical for quality and longevity of new paint. They also know that thick paint removal is a pain. Plus, most paint applied before 1978 is lead-based. With the new EPA's RRP rule, dry abrasive methods such as power sanding, power planing, and mechanical scraping without vacuum attachments are prohibited; so is high temperature heat gun usage. These methods create and disperse lead dust, chips, and vapors which are seriously harmful to children and adults. Some contractors are upset with the requirements imposed by RRP, but the US is way behind European countries in regard to lead paint safety.

In the late 1980s, a safer and more eco-friendly method was developed in Sweden by a historic restoration painter. This method uses mid-range, infrared heat waves to heat both the substrate and the paint at a lower temperature. Therefore, it greatly reduces the hazards of removing lead-based paint in three ways:

- Metallic lead vaporizes at 1,100°F (the temperature at which high heat guns operate). The mid-range infrared heat waves heat the paint and wood only to 400-600º F. Dangerous lead fumes are not released.

- Containing lead dust is difficult and costly but critical to prevent operator, building occupants, and the environment from being contaminated. The scraping of the soft paint created by the infrared heat generates minimum dust; dry scraping, sanding or shaving paint creates lots.

- The soft paint scrapings clump together and drop onto a plastic sheeting; they are easier to contain and bag up. While pressure washing surfaces may be faster, it leaves water full of paint chips in the work area’s soil, making it difficult to clean up without removing the top soil itself. Use of toxic or non-toxic chemical paint removers leaves messy goo also difficult to contain.

Another key consideration in paint removal is the impact on wood, especially old, more valuable wood. Chemicals leach out natural resins and leave residue even after rinsing. High heat (1,100ºF) guns force paint pigment back into the wood and risk scorching and igniting wood. Sanding and shaving leave gouge and burn marks if not done skillfully. Pressure washing and new steam paint removal methods often leave irregular surface marks in the wood, drive moisture back into the wood, and create layers of “gray wood” which must be scraped away and or they will threaten the adherence of new paint. All of these methods can damage wood.

Another key consideration in paint removal is the impact on wood, especially old, more valuable wood. Chemicals leach out natural resins and leave residue even after rinsing. High heat (1,100ºF) guns force paint pigment back into the wood and risk scorching and igniting wood. Sanding and shaving leave gouge and burn marks if not done skillfully. Pressure washing and new steam paint removal methods often leave irregular surface marks in the wood, drive moisture back into the wood, and create layers of “gray wood” which must be scraped away and or they will threaten the adherence of new paint. All of these methods can damage wood.

Infrared heat paint removal can be the gentlest process on the wood. The infrared heat penetrates into the wood and pulls up natural resins, paint, and moisture deep within and rejuvenates the old wood. Yet, the lower temperature of 400-600° F. minimizes the risk of scorching the wood or catching it on fire. The stories of these heat gun fires are legendary.

The time for the entire surface preparation process is reduced using the infrared heat method. Set up, operation, and cleanup are faster than with other methods. There is no extra time for rinsing, neutralization, drying, or sanding the wood; it is immediately ready for primer.

The time for the entire surface preparation process is reduced using the infrared heat method. Set up, operation, and cleanup are faster than with other methods. There is no extra time for rinsing, neutralization, drying, or sanding the wood; it is immediately ready for primer.

Since there are several brands of infrared paint removers on the market, look for these qualities:

- UL listing to verify safety testing.

- Shock absorbers to reduce bulb breakage.

- Automatic, overheat shut-off mechanism to prevent damage to the machine and the wood and to prevent paint overheating.

- Built-in safety shields extending beyond the infrared bulbs that set the correct distance between the bulbs and the painted wood. These shields eliminate the operator’s guesswork about what distance is safe yet effective and also reduce overheating.

- Comprehensive instruction materials and training videos to assure quick operator proficiency, safe operation, and proper maintenance of the machine.

Infrared heat for paint removal is a new technology whose time has come. Preservation of older homes rather than demolition is growing. People are choosing to rejuvenate their old homes for aesthetic, historic, and ecological reasons. Infrared paint removal offers a safer, gentler, and more ecological method to remove lead-based paint and bringing old wood back to life.

Contact: Catherine Brooks, Eco-Strip LLC with questions at cbrooks@eco-strip.com. Further information is at www.eco-strip.com

Looking for accurate information about the EPA RRP rule?

Looking for accurate information about the EPA RRP rule?  isclaimer: This post is shared for informational purposes only. I have no experience or any financial arrangement with these companies.

isclaimer: This post is shared for informational purposes only. I have no experience or any financial arrangement with these companies.

Another key consideration in paint removal is the impact on wood, especially old, more valuable wood. Chemicals leach out natural resins and leave residue even after rinsing. High heat (1,100ºF) guns force paint pigment back into the wood and risk scorching and igniting wood. Sanding and shaving leave gouge and burn marks if not done skillfully. Pressure washing and new steam paint removal methods often leave irregular surface marks in the wood, drive moisture back into the wood, and create layers of “gray wood” which must be scraped away and or they will threaten the adherence of new paint. All of these methods can damage wood.

Another key consideration in paint removal is the impact on wood, especially old, more valuable wood. Chemicals leach out natural resins and leave residue even after rinsing. High heat (1,100ºF) guns force paint pigment back into the wood and risk scorching and igniting wood. Sanding and shaving leave gouge and burn marks if not done skillfully. Pressure washing and new steam paint removal methods often leave irregular surface marks in the wood, drive moisture back into the wood, and create layers of “gray wood” which must be scraped away and or they will threaten the adherence of new paint. All of these methods can damage wood. The time for the entire surface preparation process is reduced using the infrared heat method. Set up, operation, and cleanup are faster than with other methods. There is no extra time for rinsing, neutralization, drying, or sanding the wood; it is immediately ready for primer.

The time for the entire surface preparation process is reduced using the infrared heat method. Set up, operation, and cleanup are faster than with other methods. There is no extra time for rinsing, neutralization, drying, or sanding the wood; it is immediately ready for primer.

“Number of events and individuals affected: In the first year that all of the rule requirements will be in effect, there will be an estimated 8.4 million renovation, repair, and painting events where lead-safe work practices will be used due to the rule. As a result, there will be approximately 1.4 million children under the age of 6 who will be affected by having their exposure to lead dust minimized due to the rule. There will also be about 5.4 million adults who will be affected. After improved test kits for determining whether a painted surface contains lead-based paint become available (which is assumed in the analysis to occur by the second year of the rule), the number of renovation, repair, and painting events using lead-safe work practices is expected to drop to 4.4 million events per year. No change in the number of exposures avoided due to the rule is expected because the improved test kit will more accurately identify paint without lead, thus reducing the number of events unnecessarily using the required work practices.”

“Number of events and individuals affected: In the first year that all of the rule requirements will be in effect, there will be an estimated 8.4 million renovation, repair, and painting events where lead-safe work practices will be used due to the rule. As a result, there will be approximately 1.4 million children under the age of 6 who will be affected by having their exposure to lead dust minimized due to the rule. There will also be about 5.4 million adults who will be affected. After improved test kits for determining whether a painted surface contains lead-based paint become available (which is assumed in the analysis to occur by the second year of the rule), the number of renovation, repair, and painting events using lead-safe work practices is expected to drop to 4.4 million events per year. No change in the number of exposures avoided due to the rule is expected because the improved test kit will more accurately identify paint without lead, thus reducing the number of events unnecessarily using the required work practices.” While at the workshop I found one thing the main instructor Darcy Cook of Safety Trainers said to be very important for contractors to be aware of. Under the OSHA Lead in Construction Standard, contractors must assume their employees will be exposed to lead above OSHA’s established action level requiring the use of respirators until they actually conduct air monitoring testing to prove otherwise.

While at the workshop I found one thing the main instructor Darcy Cook of Safety Trainers said to be very important for contractors to be aware of. Under the OSHA Lead in Construction Standard, contractors must assume their employees will be exposed to lead above OSHA’s established action level requiring the use of respirators until they actually conduct air monitoring testing to prove otherwise. So, under OSHA requirements, before allowing them to do RRP related work or even enter a contained work area, employees must first be sent to a physician to be sure they are healthy enough to wear a respirator. Then they must be fit tested by a professional and provided with a properly fitted respirator that protects them from worst case lead exposure scenarios based on the kind of work they do. They must also be trained how to select, use, clean and store a respirator. And, they must wear the respirator until the air monitoring testing is done to identify when a respirator is required and when it is not depending on how the work is performed and what engineering controls are being used.

So, under OSHA requirements, before allowing them to do RRP related work or even enter a contained work area, employees must first be sent to a physician to be sure they are healthy enough to wear a respirator. Then they must be fit tested by a professional and provided with a properly fitted respirator that protects them from worst case lead exposure scenarios based on the kind of work they do. They must also be trained how to select, use, clean and store a respirator. And, they must wear the respirator until the air monitoring testing is done to identify when a respirator is required and when it is not depending on how the work is performed and what engineering controls are being used.

Given the choice, as Massachusetts and EPA authorized RRP instructor, I will definitely use the Lead Check Swabs in my training classes. I offer some reasons for this choice below. However keep in mind, if you do RRP renovations, you will likely be choosing which test lead test kit to use and why for different reasons than I would as an instructor. I hope the information below helps you make a good decision when you select a lead test kit. Please feel free to add any other comparisons or consideration for choosing a lead test kit by commenting at the end of this article.

Given the choice, as Massachusetts and EPA authorized RRP instructor, I will definitely use the Lead Check Swabs in my training classes. I offer some reasons for this choice below. However keep in mind, if you do RRP renovations, you will likely be choosing which test lead test kit to use and why for different reasons than I would as an instructor. I hope the information below helps you make a good decision when you select a lead test kit. Please feel free to add any other comparisons or consideration for choosing a lead test kit by commenting at the end of this article. The RRP rule requires that dust and debris be controlled in the work area while working in homes built prior to 1978 unless all effected components of the renovation are properly tested and lead is not found. You can find information about the legal definition of lead paint and the accuracy of testing methods

The RRP rule requires that dust and debris be controlled in the work area while working in homes built prior to 1978 unless all effected components of the renovation are properly tested and lead is not found. You can find information about the legal definition of lead paint and the accuracy of testing methods  Required containment is similar for all jobs, but jobs that generate more dust and debris may require protection of larger areas. While the Rule does not require vertical containment, such systems may be helpful in limiting the size of the area affected by the work and may reduce the area that must be cleaned at the end of the job. Pre-engineered containment systems (purchased and home-made) are very helpful in cutting time spent on the job erecting containment and are easier to install than hanging plastic sheeting with tape. These systems also allow the contractor to create a sealed room within a room where the dust can be completely contained to a limited and controlled area.

Required containment is similar for all jobs, but jobs that generate more dust and debris may require protection of larger areas. While the Rule does not require vertical containment, such systems may be helpful in limiting the size of the area affected by the work and may reduce the area that must be cleaned at the end of the job. Pre-engineered containment systems (purchased and home-made) are very helpful in cutting time spent on the job erecting containment and are easier to install than hanging plastic sheeting with tape. These systems also allow the contractor to create a sealed room within a room where the dust can be completely contained to a limited and controlled area.  •

• EPA Communication to EPA Region Headquarters:

EPA Communication to EPA Region Headquarters: