NARI Member Testifies Before Small Business Committee About Frustrations With EPA

Yesterday, David Merrick, chairman of the NARI Government Affairs Committee and owner of Merrick Design and Build, testified before the House Small Business Committee about many of the concerns remodelers' have about the RRP Rule and the difficulties trying to effectively work with EPA. I think David’s testimony spoke for the opinions of most NARI Members as well as for most remodelers. Let me know what you think.

Click here to view the entire video which was just over one hour long. David’s introduction and his testimony begin at about 19:50.

Here are some highlights I pulled from watching the video myself.

In response to questions posed by a representative overseeing the SBA (Ms. Peters?), David stands up for and points out the realities and challenges for smaller one or two man remodeling businesses starting at about 30:28. David stressed the burden record keeping has on such smaller businesses just trying to earn enough money within the time they have to produce their product, pointing out that even if they are doing the right things regarding the work they perform, they can be punished by EPA for paperwork challenges.

Many might miss this watching the video, but I think it exposes the lack of understanding many of those in our government have about the nature of the remodeling industry and the businesses that participate in the industry. The same representative overseeing the SBA (Ms. Peters?) made the following comment at about 33:10 in what I observed to be an obvious effort to be sarcastic;

“And when I get my bid from a contractor on remodeling should I triple the time and double the money? (She laughs) Just Kidding…”

Perhaps, like many contractors, EPA has a problem under estimating and under bidding?

At 58:56 Mr. Tipton asks: “So, effectively what you are saying is if the EPA is asking for input maybe it would be a good idea if they listened? To that question Merrick replied that the EPA is always gracious about meeting with NARI and taking their input, but he further clarifies his response by commenting “They take our comments and disappear behind doors and we never hear from them again.”

At 58:56 Mr. Tipton asks: “So, effectively what you are saying is if the EPA is asking for input maybe it would be a good idea if they listened? To that question Merrick replied that the EPA is always gracious about meeting with NARI and taking their input, but he further clarifies his response by commenting “They take our comments and disappear behind doors and we never hear from them again.”

I think it is worth listening to the balance of the video after Merrick’s comment to hear Mr. Tipton’s comments and opinions in support of more sensible oversight of EPA’s tactics, behavior, attitudes and performance.

Give EPA more money?

During the hearing there was much banter regarding whether EPA needs more money to effectively regulate or alternately should get less money because of their poor performance. I think they are missing the point. We don’t have more money to give EPA unless we take it from somewhere else or borrow it from China and put the burden of paying for the borrowed money on our children’s future. Maybe many of the the same children the rule is intended to protect.

Here is one example. During the hearing Merrick points out That currently only 122,476 firms in the remodeling sector are considered EPA Lead-Certified Firms, out of the estimated 652,206 remodeling businesses in the United States. Has EPA done a good job in the past 26 months since the rule took effect if 80% of remodeling contractors are still operating uncertified? Are they really keeping our children safe from lead poisoning with the plan they assembled knowing the reality of available funding?

I think it goes back to original planning. Try this analogy.

The simple way to put it is it’s great to figure out and plan for a nice seafood lobster dinner, but if you get to the store and you don’t have enough money then all that planning on a great seafood dinner is kind of wasted. My suggestion is that the way EPA went about creating this rule is rather silly especially because they just don’t have the funding or the budget to administer and enforce the rule the way the rule was written.

Perhaps if EPA really understood our industry and how contractors operate, they would have considered a Design/Build approach!

Thanks David.

Click here for a NARI Press Release about the hearing

Looking for accurate information about the EPA RRP rule?

Looking for accurate information about the EPA RRP rule?  As EPA amends the RRP rule, renovators working in states that have taken over the rule from EPA need to know if and how these states incorporate the changes into their own rule. Yesterday I inquired with the State of Massachusetts to find out about a few recent amendments and changes.

As EPA amends the RRP rule, renovators working in states that have taken over the rule from EPA need to know if and how these states incorporate the changes into their own rule. Yesterday I inquired with the State of Massachusetts to find out about a few recent amendments and changes. Question: Can you tell me if MA allows the lead safe renovation supervisor to take paint chip samples same as EPA does?

Question: Can you tell me if MA allows the lead safe renovation supervisor to take paint chip samples same as EPA does? Question: Also, does MA now recognize LeadCheck for Drywall and Plaster?

Question: Also, does MA now recognize LeadCheck for Drywall and Plaster? I suggest the real problem is that the original rule was poorly conceived and poorly written. Because we are now stuck with it, the proposed amendments are really just band-aid approaches to try to make it better for or more palatable to those affected by the rule. What we really need is a new well thought out rule to replace the existing rule, with the input and leadership of the industry this time. And, the industry needs to be proactive this time in its writing, its content and its enforcement.

I suggest the real problem is that the original rule was poorly conceived and poorly written. Because we are now stuck with it, the proposed amendments are really just band-aid approaches to try to make it better for or more palatable to those affected by the rule. What we really need is a new well thought out rule to replace the existing rule, with the input and leadership of the industry this time. And, the industry needs to be proactive this time in its writing, its content and its enforcement. Not using lead safe practices on a pre 1978 property is a big risk. Unless the house is pretested before renovations there is no point of reference regarding existing contamination. If lead safe work practices are not used, how will the business prove it did not cause the contamination?

Not using lead safe practices on a pre 1978 property is a big risk. Unless the house is pretested before renovations there is no point of reference regarding existing contamination. If lead safe work practices are not used, how will the business prove it did not cause the contamination?

Legislation introduced by Senator Inhofe (R) will soon be before the US Senate for consideration. Inhofe introduced Bill 2148, the

Legislation introduced by Senator Inhofe (R) will soon be before the US Senate for consideration. Inhofe introduced Bill 2148, the  Unfortunately we are stuck with the RRP Rule. Maybe the best we can do is try to improve upon it.

Unfortunately we are stuck with the RRP Rule. Maybe the best we can do is try to improve upon it. This one requires EPA to actually use science to justify its position regarding any future RRP related regulations related to residential as well as commercial properties:

This one requires EPA to actually use science to justify its position regarding any future RRP related regulations related to residential as well as commercial properties:

The definition of ‘readily available’ varies widely. For example, OSHA allows up to 24 hours for businesses to produce some types of required records. When the EPA inspector walks in and asks for your RRP documents, you should be able to open a file drawer, pull out a box, or hand them a CD with all of your records within a 15 to 30 minute time frame. Otherwise, they pull out their ticket book and start writing violations.

The definition of ‘readily available’ varies widely. For example, OSHA allows up to 24 hours for businesses to produce some types of required records. When the EPA inspector walks in and asks for your RRP documents, you should be able to open a file drawer, pull out a box, or hand them a CD with all of your records within a 15 to 30 minute time frame. Otherwise, they pull out their ticket book and start writing violations. EPA does not allow hearsay compliance. If it isn’t written down, it didn’t happen. You can stand there and tell them that you used containment on every job. But, a picture of your jobsites with you pointing to the warning sign outside your containment demonstrates compliance beyond any doubt. Pictures are worth a thousand words…and don’t forget to set your date and time stamp on your photo.

EPA does not allow hearsay compliance. If it isn’t written down, it didn’t happen. You can stand there and tell them that you used containment on every job. But, a picture of your jobsites with you pointing to the warning sign outside your containment demonstrates compliance beyond any doubt. Pictures are worth a thousand words…and don’t forget to set your date and time stamp on your photo.

Renovators should be aware that in addition to EPA or administering states, other individuals or entities may likely take advantage of the documentation requirements to hold renovators accountable for their actions or lack thereof.

Renovators should be aware that in addition to EPA or administering states, other individuals or entities may likely take advantage of the documentation requirements to hold renovators accountable for their actions or lack thereof. OSHA could use RRP paperwork to prove non-compliance with its Lead in Construction Standards. OSHA’s worker protection requirements related to lead are very specific. Information contained in the required RRP documentation, particularly the renovation checklist and non-certified worker training documentation, could easily be used to show workers were not adequately trained and or protected when working in contained work areas. A lack of the required documentation could also be used by OSHA to demonstrate negligence by the business.

OSHA could use RRP paperwork to prove non-compliance with its Lead in Construction Standards. OSHA’s worker protection requirements related to lead are very specific. Information contained in the required RRP documentation, particularly the renovation checklist and non-certified worker training documentation, could easily be used to show workers were not adequately trained and or protected when working in contained work areas. A lack of the required documentation could also be used by OSHA to demonstrate negligence by the business.  Being a landlord brings with it many legal responsibilities related to lead paint that, if not followed, can certainly eat away at any potential profits. There are many rules to consider and be aware of, the most common being the

Being a landlord brings with it many legal responsibilities related to lead paint that, if not followed, can certainly eat away at any potential profits. There are many rules to consider and be aware of, the most common being the  When work is done inside their units, tenants must be given an EPA published pamphlet titled “Renovate Right”. The pamphlet explains the dangers of lead and what is required to protect their and their family’s health and safety when work is being done at the property where they live. If work is to be done in common areas, the pamphlet can either be given to tenants, or, notices can be posted telling tenants how they can receive the pamphlet at no cost to them. Tenants must also be given or made aware how they can request a document titled the

When work is done inside their units, tenants must be given an EPA published pamphlet titled “Renovate Right”. The pamphlet explains the dangers of lead and what is required to protect their and their family’s health and safety when work is being done at the property where they live. If work is to be done in common areas, the pamphlet can either be given to tenants, or, notices can be posted telling tenants how they can receive the pamphlet at no cost to them. Tenants must also be given or made aware how they can request a document titled the  If the landlord does his own work on the rental property and or uses his/her own employees to do so, the landlord must also become an EPA Certified RRP firm and only use trained and certified workers to do the work. If you are a landlord doing your own work,

If the landlord does his own work on the rental property and or uses his/her own employees to do so, the landlord must also become an EPA Certified RRP firm and only use trained and certified workers to do the work. If you are a landlord doing your own work,  NOTE: If you are a landlord, realtor or member of a group representing landlords or realtors seeking help and information about the RRP rules, feel free to

NOTE: If you are a landlord, realtor or member of a group representing landlords or realtors seeking help and information about the RRP rules, feel free to  The New Renovation Repair and Painting Rule could likely be a ticking time bomb for many renovators who are ignorant of, intentionally ignoring and or not following all of the many requirements of the rule. The reason I say this is because of the documentation and record keeping requirements of the RRP Rule. Renovators should keep in mind that under the rule the required documentation for each RRP project must be stored and made available for inspection for up to 3 years after the completion of the project. The EPA and or states that have taken over administration and enforcement of the rule won’t be limited to finding active violations of the rule on jobsites. They will also be able to use the required documentation to determine whether renovators were complying with the rule on all projects completed in the three years preceding an inspection. Check out this

The New Renovation Repair and Painting Rule could likely be a ticking time bomb for many renovators who are ignorant of, intentionally ignoring and or not following all of the many requirements of the rule. The reason I say this is because of the documentation and record keeping requirements of the RRP Rule. Renovators should keep in mind that under the rule the required documentation for each RRP project must be stored and made available for inspection for up to 3 years after the completion of the project. The EPA and or states that have taken over administration and enforcement of the rule won’t be limited to finding active violations of the rule on jobsites. They will also be able to use the required documentation to determine whether renovators were complying with the rule on all projects completed in the three years preceding an inspection. Check out this I had a conversation with one remodeler about the serious risks non-compliance can have for a renovator’s business. His opinion was that the risk of being caught was dependent on “how legal” the remodeler is in the way he/she operates the business. My opinion is that being legal is not measured on any kind of graduated scale. You are either operating the business legally or you are not. I think both EPA and OSHA agree with this logic.

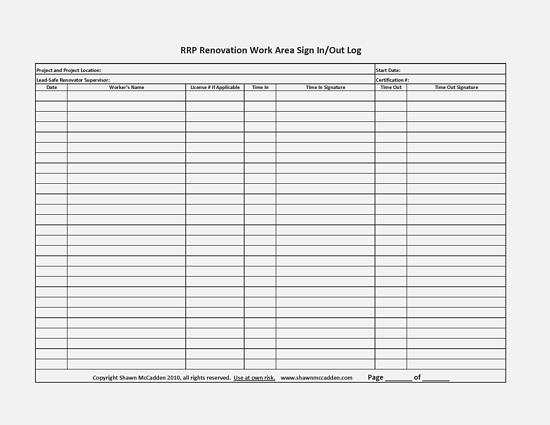

I had a conversation with one remodeler about the serious risks non-compliance can have for a renovator’s business. His opinion was that the risk of being caught was dependent on “how legal” the remodeler is in the way he/she operates the business. My opinion is that being legal is not measured on any kind of graduated scale. You are either operating the business legally or you are not. I think both EPA and OSHA agree with this logic.  One of the differences between the EPA RRP Rule and the Massachusetts RRP Rule is that Massachusetts requires the Licensed Lead-Safe Renovation Contractor (firm) to maintain a sign in/out log, just like the one required for deleading contractors, for workers who enter and exit the contained work area during RRP renovations.

One of the differences between the EPA RRP Rule and the Massachusetts RRP Rule is that Massachusetts requires the Licensed Lead-Safe Renovation Contractor (firm) to maintain a sign in/out log, just like the one required for deleading contractors, for workers who enter and exit the contained work area during RRP renovations.

This is an excellent observation and question. The liability in such a situation is huge. I just recently had a conversation about this topic with an attorney well familiar with the RRP rule. Her suggestion was to consider asking the home owner to do testing of the occupants and perhaps even dust wipe testing at the home before beginning any work to establish a point of reference. Discussing this with and asking the home owner to do so would obviously be a sensitive conversation and could likely be a tough sell for many contractors.

This is an excellent observation and question. The liability in such a situation is huge. I just recently had a conversation about this topic with an attorney well familiar with the RRP rule. Her suggestion was to consider asking the home owner to do testing of the occupants and perhaps even dust wipe testing at the home before beginning any work to establish a point of reference. Discussing this with and asking the home owner to do so would obviously be a sensitive conversation and could likely be a tough sell for many contractors.