Compliance With and Enforcement of the RRP Rule Will Be Assisted By OSHA Inspectors

In addition to the OSHA rules contractors should already have been aware of related to worker safety, the EPA RRP rule has added yet additional OSHA concerns for renovators. One for example is working on a surface covered with plastic. OSHA considerations related to working on plastic are not part of the curriculum delivered during the required EPA certified renovator training. Due to the absence of this information, the EPA is essentially leaving it up to renovators to become aware of such considerations on their own. Once aware, renovators must seek out the information they need and adjust their work practices accordingly to avoid fines from OSHA should they get randomly inspected. Or worse, have a worker accident.

In addition to the OSHA rules contractors should already have been aware of related to worker safety, the EPA RRP rule has added yet additional OSHA concerns for renovators. One for example is working on a surface covered with plastic. OSHA considerations related to working on plastic are not part of the curriculum delivered during the required EPA certified renovator training. Due to the absence of this information, the EPA is essentially leaving it up to renovators to become aware of such considerations on their own. Once aware, renovators must seek out the information they need and adjust their work practices accordingly to avoid fines from OSHA should they get randomly inspected. Or worse, have a worker accident.

This begs a few questions. First, were the authors ignorant of such considerations? Asked another way, does the left hand know what the right hand is doing? Is this another example of a breakdown in communication between very significant departments of our government charged to look out for our best interests? A second question might be; did the authors of the EPA RRP rule leave this information out of the rule for a strategic purpose? Perhaps this is just one more way to force small independent businesses out of the construction industry in favor or labor unions.

This begs a few questions. First, were the authors ignorant of such considerations? Asked another way, does the left hand know what the right hand is doing? Is this another example of a breakdown in communication between very significant departments of our government charged to look out for our best interests? A second question might be; did the authors of the EPA RRP rule leave this information out of the rule for a strategic purpose? Perhaps this is just one more way to force small independent businesses out of the construction industry in favor or labor unions.

In one of his recent blogs, RRP certification training provider and business coach, Mark Paskell of The Contractor Coaching Partnership, shares a real life story about a contractor who was visited, at the same time, by both an OSHA inspector as well as an inspector from the Massachusetts Department of Occupational Safety (DOS). (Massachusetts has assumed administration and enforcement of the RRP rule from EOPA) In the blog Mark describes the battle that took place between the OSHA inspector and the DOS inspector about the use of plastic on the jobsite. Check out the blog to see which inspector retreated.

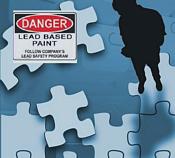

Of bigger concern should be the distribution of misinformation at the certified renovator training. For example, using the sample signage included in the EPA approved training manual (required to be posted outside contained work areas), might just get you in trouble with OSHA. First off the RRP rule requires the use of a “warning” sign, but the sample sign is a “caution” sign. OSHA considers a warning sign to be a stronger message than a caution sign, and has rules dictating when and how to choose one versus the other.

Of bigger concern should be the distribution of misinformation at the certified renovator training. For example, using the sample signage included in the EPA approved training manual (required to be posted outside contained work areas), might just get you in trouble with OSHA. First off the RRP rule requires the use of a “warning” sign, but the sample sign is a “caution” sign. OSHA considers a warning sign to be a stronger message than a caution sign, and has rules dictating when and how to choose one versus the other.

Also, if you have employees, the sample sign in the manual will not meet OSHA requirements either. Employees must be told what they are being warned about on such signs, in this case lead, and the signs must also instruct the employees not to smoke, eat, or drink in a work area assumed to contain lead. Check out this article by Dick Hughes of Excellence in Safety for a list of other OSHA requirements left out of the RRP rule.

The RRP is challenging enough to comply with. Contractors putting their heads in the sand about OSHA requirements and compliance are taking a huge risk. I am planning on taking some OSHA training classes to learn more about what contractors must need to be aware of and what they will need to do to avoid risking violations and fines. I will post information about this subject to RRPedia in the future. If you have not done so already, you can subscribe to RRPedia at the top of this page. Subscribers will be notified by e-mail as soon as new articles are posted.

Looking for accurate information about the EPA RRP rule?

Looking for accurate information about the EPA RRP rule?