RRP Rule: Is it a Sheep in Wolf's Clothing?

One Person’s Opinion: This is a guest blog submitted by Joe Levitch of Levco Builders to express his opinion. Joe is a remodeling contractor and he is also a Licensed Lead Inspector, Licensed Risk assessor and the owner of Lead Locators, a lead inspection firm in Boise Idaho. He comments and contributes to RRPedia quite often. If you would like to express your opinion or offer something of value for RRPedia visitors let me know.

Wolf in Sheep's Clothing?

It has been 2 years now and the EPA's RRP rule has been an enigma to deal with. What I envisioned as game changing regulation has turned out to be a sheep in wolfs clothing. I expected a year of educating the public through infomercials and campaigns, Then some head turning enforcement. Sadly I was and have been consistently disappointed. I expected my fellow remodelers to understand intuitively that the old days of dusty demolition were over and adopt the new rules, but there I go again over estimating my industry.

Resistance to change seems to dominate

Turns out remodelers like everyone else wants to do as little as possible and get by. Change is painful I suppose, most would rather spend energy disputing scientific facts than getting their act together and incorporating lead testing and LSWP into their SOP'S.

I have talked till blue in the face about the federal law and the mandate that RRP imposed back in April of 2010 but in my little hamlet of Boise Idaho there has been no known enforcement. I do see a trend however in the industry. We are getting a few more requests to verify contractors are using Best Practices when LSWP is in process. I am also getting an up tic in the number of test requests for lead testing, so the news is not all bad.

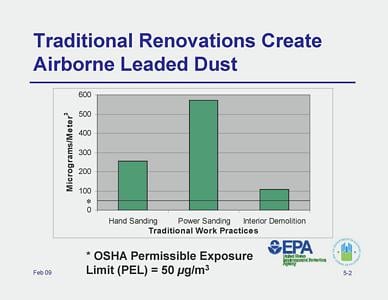

There have been a few reports of fines, but they are not close to home or particularly relevant to the remodeling industry. Most are for failure to use the Renovate Right Booklet. OSHA has become a bit more worrisome to contractors than it used to be. Their requirements are far more burdensome and onerous. I seriously doubt many remodeling firms are in compliance with their rules.

Contractors are "Leaded-Out"

I still sense a general disdain for the RRP rule along with general confusion, but a reluctant sluggish move towards compliance.

I set up a Lead Awareness committee for my NARI group and after an enthusiastic push to get everyone up to date and compliant, I was told to back off with the education and speakers " We are a little leaded-out right now"

I have had no problem explaining to my clients that lead testing saves money. Perhaps it is just the delivery I use? Doing leaded work has been difficult. I can see how one can develop heat exhaustion or worse in little or no time. Monitor your folks for hydration and schedule cooling off time.

On testing and the Opt-Out

I am saddened by remodeling organizations asking congress to repeal RRP or allow opt out. It is a huge step backwards. Having swabs check for lead in drywall and plaster was a foolish thing to allow too. I read that there is a 98% false positive when used in this way. That is why the EPA could care less. (Click here for clarity on false positives)

The swabs test for the presence of lead. We don't need to do LSWP unless there is over 1mg/cm 2. 3M is laughing all the way to the bank, homeowners and contractors alike are using LSWP unnecessarily in many cases now.

My advice to every remodeler is to find a company with an XRF that can do a test and produce a report that can be used as a tool to deal with lead above the regulatory limit. Get fluent in using LSWP. Check each other to make sure no one is poisoning their clients or their pets and lets be professional about it.

My advice to every remodeler is to find a company with an XRF that can do a test and produce a report that can be used as a tool to deal with lead above the regulatory limit. Get fluent in using LSWP. Check each other to make sure no one is poisoning their clients or their pets and lets be professional about it.

My company has teamed up with some painters that are certified firms and have done testing on all proposed renovations on all pre '78 homes. Many of them are leaded, most have only a few components that require LSWP. We have also had tiles tested and found a many of them to be leaded in a very high percentage. I believe tile should be assumed to be leaded and demolished with care.

Let's do the right thing

In closing I applaud those that have incorporated RRP into their business. The EPA has been looking into new ways to track compliance and performing enforcement. I encourage those that are resisting change to get on board before the EPA fines you, or worse, you make someone sick. Ask those of us that are dealing with the rule how we have managed and let's set ourselves apart from our competition by doing the right thing.

Looking for accurate information about the EPA RRP rule?

Looking for accurate information about the EPA RRP rule?

There have been some discussions where a particular contractor talks about how RRP is impossible to follow; only to find out the contractor has never done an RRP job … or even taken the course. Others talk about how they don’t need anyone to tell them how to clean up after a lead based paint project. Yet, they have never done a lead dust test to see if they really are cleaning up correctly. One contractor talked about how his employees were safe working around lead paint, but had never done air monitoring to see if it was true. Once, I had a contractor tell me I was doing risk assessment wrong. Yep … you guessed it. He never had done a risk assessment, taken a risk assessor course or even taken a lead safe work practice class of any type.

There have been some discussions where a particular contractor talks about how RRP is impossible to follow; only to find out the contractor has never done an RRP job … or even taken the course. Others talk about how they don’t need anyone to tell them how to clean up after a lead based paint project. Yet, they have never done a lead dust test to see if they really are cleaning up correctly. One contractor talked about how his employees were safe working around lead paint, but had never done air monitoring to see if it was true. Once, I had a contractor tell me I was doing risk assessment wrong. Yep … you guessed it. He never had done a risk assessment, taken a risk assessor course or even taken a lead safe work practice class of any type. The reality is an expert is someone who has education and experience in the subject being discussed. I like how Wikipedia states it … “experts have a prolonged or intense experience through practice and education in a particular field”.

The reality is an expert is someone who has education and experience in the subject being discussed. I like how Wikipedia states it … “experts have a prolonged or intense experience through practice and education in a particular field”.

In this example, I would place 3.5 mil plastic (from Home Depot), instead of the 6 mil plastic 10 feet out on the ground. Then, I would make sure doors/windows were closed, put plastic over any doors and then put up the warning sign. I would also run a plastic runner out to the dumpster and surround the ground around the dumpster with plastic. Doing the containment this way, saves me from having to wrap, bag or HEPA vac the siding (or myself). This is because I can dump the siding without ever going outside the containment area.

In this example, I would place 3.5 mil plastic (from Home Depot), instead of the 6 mil plastic 10 feet out on the ground. Then, I would make sure doors/windows were closed, put plastic over any doors and then put up the warning sign. I would also run a plastic runner out to the dumpster and surround the ground around the dumpster with plastic. Doing the containment this way, saves me from having to wrap, bag or HEPA vac the siding (or myself). This is because I can dump the siding without ever going outside the containment area. I can demo the tile, tub, shower, toilet and remove the demolition debris without doing any RRP. After that has been done, I cover up ducts with plastic, make sure windows are closed, close doors and cover with plastic, put up a warning sign and then cover the subfloor with plastic (6 feet out from where I will be working).

I can demo the tile, tub, shower, toilet and remove the demolition debris without doing any RRP. After that has been done, I cover up ducts with plastic, make sure windows are closed, close doors and cover with plastic, put up a warning sign and then cover the subfloor with plastic (6 feet out from where I will be working).  It very well could be that if you did a little homework by reading the actual law, you could reduce the cost of compliance on many jobs to less than 5%. Few contractors will lose a job because they are higher by less than 5%. Plus, with the cost less than 5%, I don’t even mention RRP to my clients during the estimation process anymore, which has helped to improve sales.

It very well could be that if you did a little homework by reading the actual law, you could reduce the cost of compliance on many jobs to less than 5%. Few contractors will lose a job because they are higher by less than 5%. Plus, with the cost less than 5%, I don’t even mention RRP to my clients during the estimation process anymore, which has helped to improve sales.

The first thing you should consider is that all bills introduced must first go to committee. The second thing you should realize is that the vast majority of bills introduced … will never get out of committee review and thus, will never get a chance to be voted on. Thirdly, even if the bill gets voted on, it must be approved by the majority of Senators (in this bill’s case). Lastly, even if passed by the Senate; the House & President must approve.

The first thing you should consider is that all bills introduced must first go to committee. The second thing you should realize is that the vast majority of bills introduced … will never get out of committee review and thus, will never get a chance to be voted on. Thirdly, even if the bill gets voted on, it must be approved by the majority of Senators (in this bill’s case). Lastly, even if passed by the Senate; the House & President must approve. The grandparent of RRP is Title X of the Housing and Community Development Act of 1992, also known as the Residential Lead-Based Paint Hazard Reduction Act of 1992 (Title X). The grandparents gave birth to the parent of RRP, Title IV—Lead Exposure Reduction, which amended the Toxic Substances Control Act (TSCA).

The grandparent of RRP is Title X of the Housing and Community Development Act of 1992, also known as the Residential Lead-Based Paint Hazard Reduction Act of 1992 (Title X). The grandparents gave birth to the parent of RRP, Title IV—Lead Exposure Reduction, which amended the Toxic Substances Control Act (TSCA). To put it simply, we need to come to grips that the RRP is most likely going to be required on public and commercial buildings. Public and commercial buildings have adults in them. Would it make sense to Opt-Out adults in target homes, but not Opt-Out adults in public and commercial buildings? Unfortunately, the answer is most likely not.

To put it simply, we need to come to grips that the RRP is most likely going to be required on public and commercial buildings. Public and commercial buildings have adults in them. Would it make sense to Opt-Out adults in target homes, but not Opt-Out adults in public and commercial buildings? Unfortunately, the answer is most likely not.

There was no mention of having to wear disposable suits, dust mask, booties or headwear. (Still might need to comply with OSHA)

There was no mention of having to wear disposable suits, dust mask, booties or headwear. (Still might need to comply with OSHA) It didn’t say I had to use 6 mil plastic, which made me happy since the 3.5 mil plastic sold at Home Depot cost less.

It didn’t say I had to use 6 mil plastic, which made me happy since the 3.5 mil plastic sold at Home Depot cost less.

Both sides of this issue have valid points to consider. Before we make rash decisions have we looked at the entire picture? We can do better than our politicians, but we must think before we act.

Both sides of this issue have valid points to consider. Before we make rash decisions have we looked at the entire picture? We can do better than our politicians, but we must think before we act. Whether the Opt Out comes back or not, what about the employees of the firms who intend on using this option? Did anyone ask those who are actually doing the work how they feel about their health risks? Will they have a voice without retaliation?

Whether the Opt Out comes back or not, what about the employees of the firms who intend on using this option? Did anyone ask those who are actually doing the work how they feel about their health risks? Will they have a voice without retaliation? I believe this law can create marketing and positioning opportunities to those who see it this way and in the process, keeps everyone safe – and for those who see it differently, it’s obviously a never ending source of complaints which has divided our industry at a time when we need each others’ back more than ever.

I believe this law can create marketing and positioning opportunities to those who see it this way and in the process, keeps everyone safe – and for those who see it differently, it’s obviously a never ending source of complaints which has divided our industry at a time when we need each others’ back more than ever.

The EPA created the RRP Rule because lead is found in many products in homes. Asbestos was also used frequently in homes in similar products such as paint, floor tiles, roofing tiles, and water pipes. It is safe to assume that where lead is present, asbestos is also near. Asbestos is only a serious health hazard when it is disturbed, which means during renovations the fibers may be set airborne and inhaled by workers.

The EPA created the RRP Rule because lead is found in many products in homes. Asbestos was also used frequently in homes in similar products such as paint, floor tiles, roofing tiles, and water pipes. It is safe to assume that where lead is present, asbestos is also near. Asbestos is only a serious health hazard when it is disturbed, which means during renovations the fibers may be set airborne and inhaled by workers.  Assume asbestos is present if you are working with an older home if it has not been tested by the owners

Assume asbestos is present if you are working with an older home if it has not been tested by the owners

Another key consideration in paint removal is the impact on wood, especially old, more valuable wood. Chemicals leach out natural resins and leave residue even after rinsing. High heat (1,100ºF) guns force paint pigment back into the wood and risk scorching and igniting wood. Sanding and shaving leave gouge and burn marks if not done skillfully. Pressure washing and new steam paint removal methods often leave irregular surface marks in the wood, drive moisture back into the wood, and create layers of “gray wood” which must be scraped away and or they will threaten the adherence of new paint. All of these methods can damage wood.

Another key consideration in paint removal is the impact on wood, especially old, more valuable wood. Chemicals leach out natural resins and leave residue even after rinsing. High heat (1,100ºF) guns force paint pigment back into the wood and risk scorching and igniting wood. Sanding and shaving leave gouge and burn marks if not done skillfully. Pressure washing and new steam paint removal methods often leave irregular surface marks in the wood, drive moisture back into the wood, and create layers of “gray wood” which must be scraped away and or they will threaten the adherence of new paint. All of these methods can damage wood. The time for the entire surface preparation process is reduced using the infrared heat method. Set up, operation, and cleanup are faster than with other methods. There is no extra time for rinsing, neutralization, drying, or sanding the wood; it is immediately ready for primer.

The time for the entire surface preparation process is reduced using the infrared heat method. Set up, operation, and cleanup are faster than with other methods. There is no extra time for rinsing, neutralization, drying, or sanding the wood; it is immediately ready for primer.

The definition of ‘readily available’ varies widely. For example, OSHA allows up to 24 hours for businesses to produce some types of required records. When the EPA inspector walks in and asks for your RRP documents, you should be able to open a file drawer, pull out a box, or hand them a CD with all of your records within a 15 to 30 minute time frame. Otherwise, they pull out their ticket book and start writing violations.

The definition of ‘readily available’ varies widely. For example, OSHA allows up to 24 hours for businesses to produce some types of required records. When the EPA inspector walks in and asks for your RRP documents, you should be able to open a file drawer, pull out a box, or hand them a CD with all of your records within a 15 to 30 minute time frame. Otherwise, they pull out their ticket book and start writing violations. EPA does not allow hearsay compliance. If it isn’t written down, it didn’t happen. You can stand there and tell them that you used containment on every job. But, a picture of your jobsites with you pointing to the warning sign outside your containment demonstrates compliance beyond any doubt. Pictures are worth a thousand words…and don’t forget to set your date and time stamp on your photo.

EPA does not allow hearsay compliance. If it isn’t written down, it didn’t happen. You can stand there and tell them that you used containment on every job. But, a picture of your jobsites with you pointing to the warning sign outside your containment demonstrates compliance beyond any doubt. Pictures are worth a thousand words…and don’t forget to set your date and time stamp on your photo.