RRP Rule: Is it a Sheep in Wolf's Clothing?

One Person’s Opinion: This is a guest blog submitted by Joe Levitch of Levco Builders to express his opinion. Joe is a remodeling contractor and he is also a Licensed Lead Inspector, Licensed Risk assessor and the owner of Lead Locators, a lead inspection firm in Boise Idaho. He comments and contributes to RRPedia quite often. If you would like to express your opinion or offer something of value for RRPedia visitors let me know.

Wolf in Sheep's Clothing?

It has been 2 years now and the EPA's RRP rule has been an enigma to deal with. What I envisioned as game changing regulation has turned out to be a sheep in wolfs clothing. I expected a year of educating the public through infomercials and campaigns, Then some head turning enforcement. Sadly I was and have been consistently disappointed. I expected my fellow remodelers to understand intuitively that the old days of dusty demolition were over and adopt the new rules, but there I go again over estimating my industry.

Resistance to change seems to dominate

Turns out remodelers like everyone else wants to do as little as possible and get by. Change is painful I suppose, most would rather spend energy disputing scientific facts than getting their act together and incorporating lead testing and LSWP into their SOP'S.

I have talked till blue in the face about the federal law and the mandate that RRP imposed back in April of 2010 but in my little hamlet of Boise Idaho there has been no known enforcement. I do see a trend however in the industry. We are getting a few more requests to verify contractors are using Best Practices when LSWP is in process. I am also getting an up tic in the number of test requests for lead testing, so the news is not all bad.

There have been a few reports of fines, but they are not close to home or particularly relevant to the remodeling industry. Most are for failure to use the Renovate Right Booklet. OSHA has become a bit more worrisome to contractors than it used to be. Their requirements are far more burdensome and onerous. I seriously doubt many remodeling firms are in compliance with their rules.

Contractors are "Leaded-Out"

I still sense a general disdain for the RRP rule along with general confusion, but a reluctant sluggish move towards compliance.

I set up a Lead Awareness committee for my NARI group and after an enthusiastic push to get everyone up to date and compliant, I was told to back off with the education and speakers " We are a little leaded-out right now"

I have had no problem explaining to my clients that lead testing saves money. Perhaps it is just the delivery I use? Doing leaded work has been difficult. I can see how one can develop heat exhaustion or worse in little or no time. Monitor your folks for hydration and schedule cooling off time.

On testing and the Opt-Out

I am saddened by remodeling organizations asking congress to repeal RRP or allow opt out. It is a huge step backwards. Having swabs check for lead in drywall and plaster was a foolish thing to allow too. I read that there is a 98% false positive when used in this way. That is why the EPA could care less. (Click here for clarity on false positives)

The swabs test for the presence of lead. We don't need to do LSWP unless there is over 1mg/cm 2. 3M is laughing all the way to the bank, homeowners and contractors alike are using LSWP unnecessarily in many cases now.

My advice to every remodeler is to find a company with an XRF that can do a test and produce a report that can be used as a tool to deal with lead above the regulatory limit. Get fluent in using LSWP. Check each other to make sure no one is poisoning their clients or their pets and lets be professional about it.

My advice to every remodeler is to find a company with an XRF that can do a test and produce a report that can be used as a tool to deal with lead above the regulatory limit. Get fluent in using LSWP. Check each other to make sure no one is poisoning their clients or their pets and lets be professional about it.

My company has teamed up with some painters that are certified firms and have done testing on all proposed renovations on all pre '78 homes. Many of them are leaded, most have only a few components that require LSWP. We have also had tiles tested and found a many of them to be leaded in a very high percentage. I believe tile should be assumed to be leaded and demolished with care.

Let's do the right thing

In closing I applaud those that have incorporated RRP into their business. The EPA has been looking into new ways to track compliance and performing enforcement. I encourage those that are resisting change to get on board before the EPA fines you, or worse, you make someone sick. Ask those of us that are dealing with the rule how we have managed and let's set ourselves apart from our competition by doing the right thing.

Looking for accurate information about the EPA RRP rule?

Looking for accurate information about the EPA RRP rule?

A recent example of this related to lead in construction is discussed in an

A recent example of this related to lead in construction is discussed in an  At the San Juan National Historic Site project eight alleged serious violations resulted from a lack of medical evaluations and fit-testing for employees using respirators, improper storage of compressed gas cylinders, no eye-wash stations where employees worked with corrosive products, an uncovered electrical receptacle, a lack of hazard communication training and material data sheets of the products used, and not implementing hazard communication and written respiratory protection programs.

At the San Juan National Historic Site project eight alleged serious violations resulted from a lack of medical evaluations and fit-testing for employees using respirators, improper storage of compressed gas cylinders, no eye-wash stations where employees worked with corrosive products, an uncovered electrical receptacle, a lack of hazard communication training and material data sheets of the products used, and not implementing hazard communication and written respiratory protection programs. “There is a new sheriff in town. Make no mistake about it; the Department of Labor is back in the enforcement business… Under my watch, enforcement of labor laws will be intensified to provide an effective deterrent to employers who put their workers’ lives at risk.”

“There is a new sheriff in town. Make no mistake about it; the Department of Labor is back in the enforcement business… Under my watch, enforcement of labor laws will be intensified to provide an effective deterrent to employers who put their workers’ lives at risk.”

The EPA created the RRP Rule because lead is found in many products in homes. Asbestos was also used frequently in homes in similar products such as paint, floor tiles, roofing tiles, and water pipes. It is safe to assume that where lead is present, asbestos is also near. Asbestos is only a serious health hazard when it is disturbed, which means during renovations the fibers may be set airborne and inhaled by workers.

The EPA created the RRP Rule because lead is found in many products in homes. Asbestos was also used frequently in homes in similar products such as paint, floor tiles, roofing tiles, and water pipes. It is safe to assume that where lead is present, asbestos is also near. Asbestos is only a serious health hazard when it is disturbed, which means during renovations the fibers may be set airborne and inhaled by workers.  Assume asbestos is present if you are working with an older home if it has not been tested by the owners

Assume asbestos is present if you are working with an older home if it has not been tested by the owners

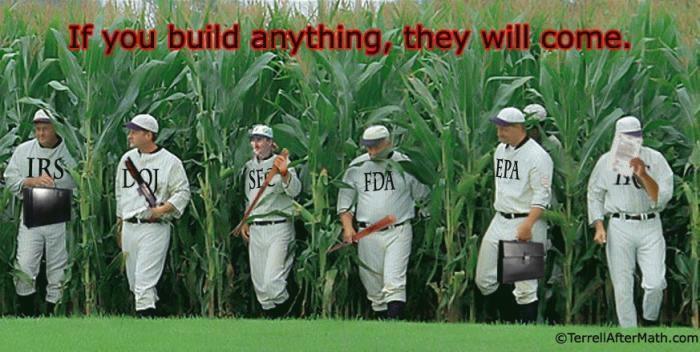

With spring only a short time away, contractors will soon be working outdoors again in the northeast. This will make the work they do and the work practices they use much more visible to OSHA and EPA. Consider yourself warned and get ready. In additional to the work practices required under RRP rules, there are plenty of OSHA regulations and requirements as well. If you don’t have written safety plans for the work your business performs, or if you have not provided the required safety training and equipment for your workers, you might become an easy target.

With spring only a short time away, contractors will soon be working outdoors again in the northeast. This will make the work they do and the work practices they use much more visible to OSHA and EPA. Consider yourself warned and get ready. In additional to the work practices required under RRP rules, there are plenty of OSHA regulations and requirements as well. If you don’t have written safety plans for the work your business performs, or if you have not provided the required safety training and equipment for your workers, you might become an easy target.

Yesterday

Yesterday  In my opinion, the ability to work with and interact with the same people who not only enforce the rule in MA, but also have the ability to help shape the MA RRP rule, has been a major plus for those Massachusetts contractors affected by the rule. At the budget hearing I shared this opinion and stressed that I hoped DOS would get adequate budgeting to keep such communication opportunities available in the future. Here are a few of the items I suggested at the hearing:

In my opinion, the ability to work with and interact with the same people who not only enforce the rule in MA, but also have the ability to help shape the MA RRP rule, has been a major plus for those Massachusetts contractors affected by the rule. At the budget hearing I shared this opinion and stressed that I hoped DOS would get adequate budgeting to keep such communication opportunities available in the future. Here are a few of the items I suggested at the hearing:

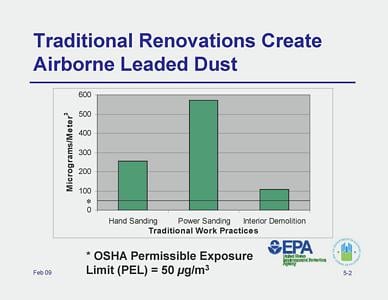

While at the workshop I found one thing the main instructor Darcy Cook of Safety Trainers said to be very important for contractors to be aware of. Under the OSHA Lead in Construction Standard, contractors must assume their employees will be exposed to lead above OSHA’s established action level requiring the use of respirators until they actually conduct air monitoring testing to prove otherwise.

While at the workshop I found one thing the main instructor Darcy Cook of Safety Trainers said to be very important for contractors to be aware of. Under the OSHA Lead in Construction Standard, contractors must assume their employees will be exposed to lead above OSHA’s established action level requiring the use of respirators until they actually conduct air monitoring testing to prove otherwise.

So, under OSHA requirements, before allowing them to do RRP related work or even enter a contained work area, employees must first be sent to a physician to be sure they are healthy enough to wear a respirator. Then they must be fit tested by a professional and provided with a properly fitted respirator that protects them from worst case lead exposure scenarios based on the kind of work they do. They must also be trained how to select, use, clean and store a respirator. And, they must wear the respirator until the air monitoring testing is done to identify when a respirator is required and when it is not depending on how the work is performed and what engineering controls are being used.

So, under OSHA requirements, before allowing them to do RRP related work or even enter a contained work area, employees must first be sent to a physician to be sure they are healthy enough to wear a respirator. Then they must be fit tested by a professional and provided with a properly fitted respirator that protects them from worst case lead exposure scenarios based on the kind of work they do. They must also be trained how to select, use, clean and store a respirator. And, they must wear the respirator until the air monitoring testing is done to identify when a respirator is required and when it is not depending on how the work is performed and what engineering controls are being used. Renovators should be aware that in addition to EPA or administering states, other individuals or entities may likely take advantage of the documentation requirements to hold renovators accountable for their actions or lack thereof.

Renovators should be aware that in addition to EPA or administering states, other individuals or entities may likely take advantage of the documentation requirements to hold renovators accountable for their actions or lack thereof. OSHA could use RRP paperwork to prove non-compliance with its Lead in Construction Standards. OSHA’s worker protection requirements related to lead are very specific. Information contained in the required RRP documentation, particularly the renovation checklist and non-certified worker training documentation, could easily be used to show workers were not adequately trained and or protected when working in contained work areas. A lack of the required documentation could also be used by OSHA to demonstrate negligence by the business.

OSHA could use RRP paperwork to prove non-compliance with its Lead in Construction Standards. OSHA’s worker protection requirements related to lead are very specific. Information contained in the required RRP documentation, particularly the renovation checklist and non-certified worker training documentation, could easily be used to show workers were not adequately trained and or protected when working in contained work areas. A lack of the required documentation could also be used by OSHA to demonstrate negligence by the business.  The New Renovation Repair and Painting Rule could likely be a ticking time bomb for many renovators who are ignorant of, intentionally ignoring and or not following all of the many requirements of the rule. The reason I say this is because of the documentation and record keeping requirements of the RRP Rule. Renovators should keep in mind that under the rule the required documentation for each RRP project must be stored and made available for inspection for up to 3 years after the completion of the project. The EPA and or states that have taken over administration and enforcement of the rule won’t be limited to finding active violations of the rule on jobsites. They will also be able to use the required documentation to determine whether renovators were complying with the rule on all projects completed in the three years preceding an inspection. Check out this

The New Renovation Repair and Painting Rule could likely be a ticking time bomb for many renovators who are ignorant of, intentionally ignoring and or not following all of the many requirements of the rule. The reason I say this is because of the documentation and record keeping requirements of the RRP Rule. Renovators should keep in mind that under the rule the required documentation for each RRP project must be stored and made available for inspection for up to 3 years after the completion of the project. The EPA and or states that have taken over administration and enforcement of the rule won’t be limited to finding active violations of the rule on jobsites. They will also be able to use the required documentation to determine whether renovators were complying with the rule on all projects completed in the three years preceding an inspection. Check out this I had a conversation with one remodeler about the serious risks non-compliance can have for a renovator’s business. His opinion was that the risk of being caught was dependent on “how legal” the remodeler is in the way he/she operates the business. My opinion is that being legal is not measured on any kind of graduated scale. You are either operating the business legally or you are not. I think both EPA and OSHA agree with this logic.

I had a conversation with one remodeler about the serious risks non-compliance can have for a renovator’s business. His opinion was that the risk of being caught was dependent on “how legal” the remodeler is in the way he/she operates the business. My opinion is that being legal is not measured on any kind of graduated scale. You are either operating the business legally or you are not. I think both EPA and OSHA agree with this logic.  On December 2nd, 2010 I attended an

On December 2nd, 2010 I attended an  At the workshop Joe Ceccarelli, a trainer with Safety Trainers, shared some information with the attendees regarding OSHA’s plans to step up inspections and increase fine amounts related to the residential construction Industry. He told us that OSHA Region 1 has hire 250 new additional field inspectors and 40 of those have been assigned to Massachusetts alone. I was quite taken back when Joe told us he had learned that 72% of OSHA violations levied against residential construction businesses were for what OSHA calls “serious or willful violations” and resulted in fines ranging from $3000 to $70,000.

At the workshop Joe Ceccarelli, a trainer with Safety Trainers, shared some information with the attendees regarding OSHA’s plans to step up inspections and increase fine amounts related to the residential construction Industry. He told us that OSHA Region 1 has hire 250 new additional field inspectors and 40 of those have been assigned to Massachusetts alone. I was quite taken back when Joe told us he had learned that 72% of OSHA violations levied against residential construction businesses were for what OSHA calls “serious or willful violations” and resulted in fines ranging from $3000 to $70,000.