What You Don’t Know About Respirators and Probably Would Rather Not Know

On December 2nd I attended an RRP/OSHA Respiratory and Worker Protection Workshop put on by The Contractor Coaching Partnership and Safety Trainers. The workshop was really helpful for me. It helped me tie together some of my open questions and concerns regarding OSHA requirements and compliance as they relate to RRP related work activities for employees.

While at the workshop I found one thing the main instructor Darcy Cook of Safety Trainers said to be very important for contractors to be aware of. Under the OSHA Lead in Construction Standard, contractors must assume their employees will be exposed to lead above OSHA’s established action level requiring the use of respirators until they actually conduct air monitoring testing to prove otherwise.

While at the workshop I found one thing the main instructor Darcy Cook of Safety Trainers said to be very important for contractors to be aware of. Under the OSHA Lead in Construction Standard, contractors must assume their employees will be exposed to lead above OSHA’s established action level requiring the use of respirators until they actually conduct air monitoring testing to prove otherwise.

This means that respirators must be worn while doing RRP work until the testing is done and a written respirator plan is put in place that details when a respirator is required and when it is not. Engineering controls can be used to limit the creation and or spread of lead dust while work is performed. The requirement to wear the respirator or not all depends on the kind of work being done as well as how the work is performed.

For example; the sanding of painted surfaces. If dry hand sanding is done, a respirator will definitely be required. If wet sanding is done a respirator may not be required. If the sanding is being done using a sander attached to a functioning HEPA Vac that captures all sanding dust, a respirator is probably not required. The previous sentence is qualified with “may” and “probably not” on purpose. The only way to know if a respirator is required or not is to monitor the air for lead dust while the work is actually being performed.

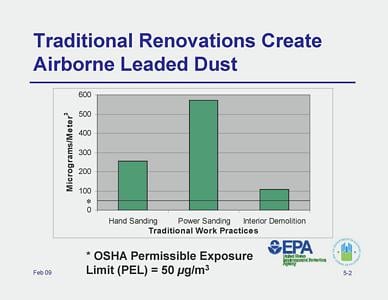

The chart below is from the EPA Certified Renovator Manual. The chart shows exposure levels of airborne leaded dust for some common renovation activities. OSHA’s permissible exposure limit (PEL) for workers is 50 Micrograms per centimeter squared (50 µg/m3). If exposed over the PEL, workers must wear respirators. All three activities in the chart exceed the PEL.

So, under OSHA requirements, before allowing them to do RRP related work or even enter a contained work area, employees must first be sent to a physician to be sure they are healthy enough to wear a respirator. Then they must be fit tested by a professional and provided with a properly fitted respirator that protects them from worst case lead exposure scenarios based on the kind of work they do. They must also be trained how to select, use, clean and store a respirator. And, they must wear the respirator until the air monitoring testing is done to identify when a respirator is required and when it is not depending on how the work is performed and what engineering controls are being used.

So, under OSHA requirements, before allowing them to do RRP related work or even enter a contained work area, employees must first be sent to a physician to be sure they are healthy enough to wear a respirator. Then they must be fit tested by a professional and provided with a properly fitted respirator that protects them from worst case lead exposure scenarios based on the kind of work they do. They must also be trained how to select, use, clean and store a respirator. And, they must wear the respirator until the air monitoring testing is done to identify when a respirator is required and when it is not depending on how the work is performed and what engineering controls are being used.

Although these OSHA requirements are not new, the majority of residential contractors are not aware of them. Unfortunately, ignorance of the requirements will not be an excuse if OSHA inspects one of your projects and or one of your employees is poisoned by lead. Perhaps it would have been helpful if EPA had included the above information in the required eight hour certified renovator training when showing the chart above.

Click here for more information about Personal Protection Equipment (PPE) required for RRP work

Click here for more about what you need to know about Respirators when doing EPA RRP work

Looking for accurate information about the EPA RRP rule?

Looking for accurate information about the EPA RRP rule?  According to

According to  Although I agree renovators should be required to work lead-safe, I suggest that the RRP rule falls way too short in preventing lead poisoning. Allowing home owners and tenants to do RRP work without the knowledge and proper training required should be considered a travesty. Without understanding how lead poisoning happens and how to perform the work in a lead-safe manner, these parents are often unknowingly poisoning their children.

Although I agree renovators should be required to work lead-safe, I suggest that the RRP rule falls way too short in preventing lead poisoning. Allowing home owners and tenants to do RRP work without the knowledge and proper training required should be considered a travesty. Without understanding how lead poisoning happens and how to perform the work in a lead-safe manner, these parents are often unknowingly poisoning their children. Lead Paint Hazard is a legal term. The following information is from the Electronic Code of Federal Regulations, Title 40: Protection of Environment,

Lead Paint Hazard is a legal term. The following information is from the Electronic Code of Federal Regulations, Title 40: Protection of Environment,  (3) Any chewable lead-based painted surface on which there is evidence of teeth marks.

(3) Any chewable lead-based painted surface on which there is evidence of teeth marks. I recently completed a series of seven videos about the new EPA RRP rule. The RRP videos were done for Remodeling magazine. They are posted to the Remodeling TV area of Remodeling magazine’s web site.

I recently completed a series of seven videos about the new EPA RRP rule. The RRP videos were done for Remodeling magazine. They are posted to the Remodeling TV area of Remodeling magazine’s web site. writing the script, interviewing contributors, editing the script with the magazine’s editor Sal Alfano, reviewing the raw footage, and working with the videographer,

writing the script, interviewing contributors, editing the script with the magazine’s editor Sal Alfano, reviewing the raw footage, and working with the videographer,  As like many of you, I have definitely exposed my body to lead over the last 30 plus years I have been involved in remodeling. As I learn more about lead poisoning and the symptoms of lead poisoning, I flash back to my younger years working for my dad’s remodeling business. Back then there was little awareness or thought given to the way we worked when disturbing lead paint. One summer I remember complaining of stomach aches, muscle pains and constantly feeling tired even after having the weekend off. My parents took me to the doctor but the doctor couldn’t find any reason for these symptoms. He gave me a terrible tasting medication to take daily and asked me to report back on how I was doing. The symptoms would seem to come and go all summer long, but then went away when I went back to college after the summer was over. This same scenario played over again the following summer.

As like many of you, I have definitely exposed my body to lead over the last 30 plus years I have been involved in remodeling. As I learn more about lead poisoning and the symptoms of lead poisoning, I flash back to my younger years working for my dad’s remodeling business. Back then there was little awareness or thought given to the way we worked when disturbing lead paint. One summer I remember complaining of stomach aches, muscle pains and constantly feeling tired even after having the weekend off. My parents took me to the doctor but the doctor couldn’t find any reason for these symptoms. He gave me a terrible tasting medication to take daily and asked me to report back on how I was doing. The symptoms would seem to come and go all summer long, but then went away when I went back to college after the summer was over. This same scenario played over again the following summer. Fortunately for me, in the early days of owning my remodeling business, I learned a lot about lead and lead safe work practices through the NARI/HUD Lead Safe Remodeler training program that came out in the mid 1990’s. The current Certified Renovator training is only one day and really only teaches attendees how to contain the dust and debris. Different than the current class, the NARI/HUD class was two days long and actually thought us lead-safe work practices that eliminated or significantly reduced the creation of lead dust and debris. Attending that class was definitely worth the investment of time and money. Both I and my employees changed the way we thought about the work we did and the methods we used going forward.

Fortunately for me, in the early days of owning my remodeling business, I learned a lot about lead and lead safe work practices through the NARI/HUD Lead Safe Remodeler training program that came out in the mid 1990’s. The current Certified Renovator training is only one day and really only teaches attendees how to contain the dust and debris. Different than the current class, the NARI/HUD class was two days long and actually thought us lead-safe work practices that eliminated or significantly reduced the creation of lead dust and debris. Attending that class was definitely worth the investment of time and money. Both I and my employees changed the way we thought about the work we did and the methods we used going forward. Lead poisoning can occur when people are exposed to large or small amounts of lead over time. Lead builds up in the body and may cause temporary or permanent damage. A blood lead test can show whether your body has absorbed a dangerous amount of lead. A high blood lead level is an indication that lead is building up in the body faster than it can be eliminated.

Lead poisoning can occur when people are exposed to large or small amounts of lead over time. Lead builds up in the body and may cause temporary or permanent damage. A blood lead test can show whether your body has absorbed a dangerous amount of lead. A high blood lead level is an indication that lead is building up in the body faster than it can be eliminated. Later Signs and Symptoms:

Later Signs and Symptoms:

The RRP rule requires that dust and debris be controlled in the work area while working in homes built prior to 1978 unless all effected components of the renovation are properly tested and lead is not found. You can find information about the legal definition of lead paint and the accuracy of testing methods

The RRP rule requires that dust and debris be controlled in the work area while working in homes built prior to 1978 unless all effected components of the renovation are properly tested and lead is not found. You can find information about the legal definition of lead paint and the accuracy of testing methods  Required containment is similar for all jobs, but jobs that generate more dust and debris may require protection of larger areas. While the Rule does not require vertical containment, such systems may be helpful in limiting the size of the area affected by the work and may reduce the area that must be cleaned at the end of the job. Pre-engineered containment systems (purchased and home-made) are very helpful in cutting time spent on the job erecting containment and are easier to install than hanging plastic sheeting with tape. These systems also allow the contractor to create a sealed room within a room where the dust can be completely contained to a limited and controlled area.

Required containment is similar for all jobs, but jobs that generate more dust and debris may require protection of larger areas. While the Rule does not require vertical containment, such systems may be helpful in limiting the size of the area affected by the work and may reduce the area that must be cleaned at the end of the job. Pre-engineered containment systems (purchased and home-made) are very helpful in cutting time spent on the job erecting containment and are easier to install than hanging plastic sheeting with tape. These systems also allow the contractor to create a sealed room within a room where the dust can be completely contained to a limited and controlled area.  •

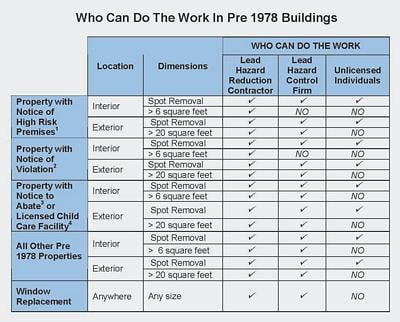

• Rhode Island has been operating a Lead-Safe Remodeler/Renovator Program since 2001 and has licensed over 1,500 Lead-Safe Remodeler/Renovators. In 2010, the Environmental Protection Agency (EPA) created its own Lead-Safe Remodeler/Renovator Program, known as the Lead-Based Paint Renovation, Repair, and Painting Rule. Rhode Island was the first New England state granted authority by EPA to continue its state Remodeler/Renovator program.

Rhode Island has been operating a Lead-Safe Remodeler/Renovator Program since 2001 and has licensed over 1,500 Lead-Safe Remodeler/Renovators. In 2010, the Environmental Protection Agency (EPA) created its own Lead-Safe Remodeler/Renovator Program, known as the Lead-Based Paint Renovation, Repair, and Painting Rule. Rhode Island was the first New England state granted authority by EPA to continue its state Remodeler/Renovator program.  Rhode Island's RRP Rule applies to contractors, landlords, property managers, homeowners, and anyone else who disturbs painted surfaces on pre-1978 homes or child care facilities. This includes general contractors as well as special trade contractors, such as painters, plumbers, carpenters, and electricians.

Rhode Island's RRP Rule applies to contractors, landlords, property managers, homeowners, and anyone else who disturbs painted surfaces on pre-1978 homes or child care facilities. This includes general contractors as well as special trade contractors, such as painters, plumbers, carpenters, and electricians.

When work is complete, Lead-Safe Remodeler/Renovators and their workers must:

When work is complete, Lead-Safe Remodeler/Renovators and their workers must: Because of one of the EPA RRP amendments, there is a new requirement regarding documentation. As of the amendment that took effect on July 6th, 2010, when the final invoice for the renovation is delivered, or within 30 days of the completion of the renovation, whichever is earlier, the renovation firm must provide information demonstrating compliance with the training and work practice requirements of the RRP rule to the owner of the building being renovated and, if different, to the occupants of the renovated housing or the operator of the child-occupied facility.

Because of one of the EPA RRP amendments, there is a new requirement regarding documentation. As of the amendment that took effect on July 6th, 2010, when the final invoice for the renovation is delivered, or within 30 days of the completion of the renovation, whichever is earlier, the renovation firm must provide information demonstrating compliance with the training and work practice requirements of the RRP rule to the owner of the building being renovated and, if different, to the occupants of the renovated housing or the operator of the child-occupied facility.

One way to think about this might be to relate it to eating fish. The government often says that if you fish in certain bodies of polluted water, you can safely eat up to so many of the fish you catch without any health concerns. If the government says you can eat up to 3 fish a year, how safe would you feel eating even one fish? Using this analogy, how safe might the owner feel having renovations done if there is any lead present at all at their property?

One way to think about this might be to relate it to eating fish. The government often says that if you fish in certain bodies of polluted water, you can safely eat up to so many of the fish you catch without any health concerns. If the government says you can eat up to 3 fish a year, how safe would you feel eating even one fish? Using this analogy, how safe might the owner feel having renovations done if there is any lead present at all at their property?