The EPA RRP Model Certified Lead Renovator Courses do not address one of the critical tasks for an renovation project: How to use and maintain the HEPA vacuum. But if a renovator gets this wrong, then HEPA may not help cleanup dust. Worse, it could spread dust and cause contamination and poisoning.

Some suggestions:

-

Cleaning: If the filter - whether the HEPA filter or the prefilters - gets loaded down with dust and debris, the HEPA vacuum will not move enough air to properly and efficiently collect lead dust and lead debris from the renovation. The renovator must periodically clean the vacuum and replace the prefilter - and depending on the design - the HEPA filter.

-

Sealing: Before you turn off a HEPA vacuum, you need to cover the end of the air intake home with tape or bag the beater bar. If you don't do this, the dust and debris in the hose will fall out and recontaminate the workplace or be released in the truck or someone else's home. When you need to use the vacuum, turn the vacuum on and then remove the tape or bag. Remember, when the unit is turned off, the air intake openings must be sealed.

-

Training: When training workers consider the following:

-

-

Consider adding a demonstration about HEPA vacuum cleaning to the training. Allow traineees to open up a HEPA vacuum and see how it works.

-

Consider having the trainees practice with a new unused HEPA vacuum so you can observe and help them. Make sure it has not been used and contaminated with lead.

-

Watch the trainees during hands-on exercises to make sure they seal up the vacuum when it is turned off. If they forget, dump the debris and dust on the cleaned up workplace for a great visual and have them reclean.

-

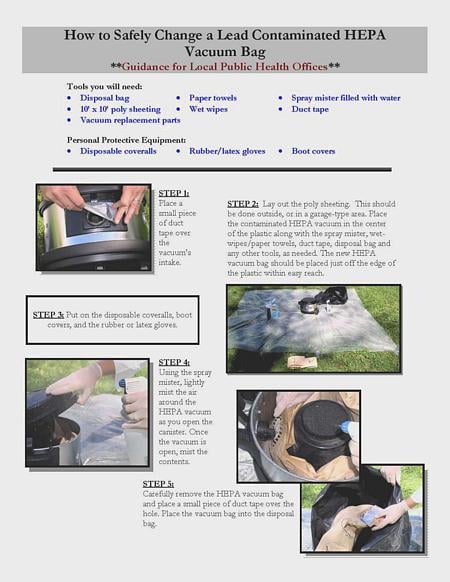

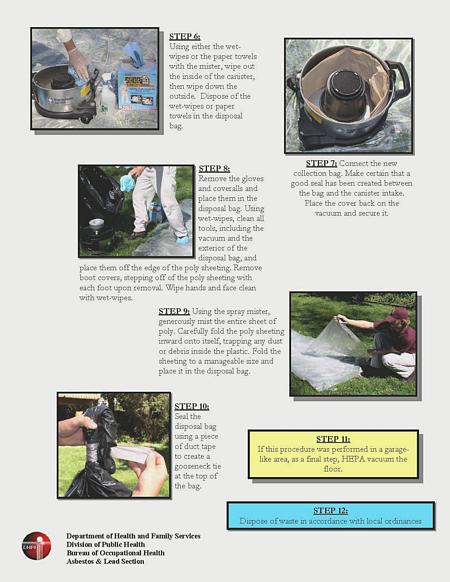

The Wisconsin Department of Health Services developed this great two-page fact sheet on "How to Safely Change a Lead Contaminated HEPA Vacuum Bag." They use a common canister vacuum to show how to change the prefilter.

Looking for accurate information about the EPA RRP rule?

Looking for accurate information about the EPA RRP rule?

Note: The final rule does not prohibit or restrict the use of dry hand sanding or dry hand scraping. EPA has concluded that it is not necessary to prohibit or restrict dry hand sanding or dry hand scraping because the containment, cleaning, and cleaning verification requirements of the rule are effective at minimizing exposure to lead-based paint hazards created by renovations and the migration of dust-lead hazards beyond the work area when dry hand sanding or dry hand scraping is employed.

Note: The final rule does not prohibit or restrict the use of dry hand sanding or dry hand scraping. EPA has concluded that it is not necessary to prohibit or restrict dry hand sanding or dry hand scraping because the containment, cleaning, and cleaning verification requirements of the rule are effective at minimizing exposure to lead-based paint hazards created by renovations and the migration of dust-lead hazards beyond the work area when dry hand sanding or dry hand scraping is employed.

Firms performing tasks that disturb no painted surfaces whatsoever do not need to be EPA Certified Firms. However, since conditions at the job site may be difficult to predict, EPA strongly recommends that all firms involved in the renovation be certified and use properly trained and certified personnel. For example, a firm hired to install an HVAC system after demolition of painted surfaces has taken place may find that to complete the job painted surfaces need to be disturbed. The HVAC firm may not engage in activities that disturb painted surfaces if it is not certified.

Firms performing tasks that disturb no painted surfaces whatsoever do not need to be EPA Certified Firms. However, since conditions at the job site may be difficult to predict, EPA strongly recommends that all firms involved in the renovation be certified and use properly trained and certified personnel. For example, a firm hired to install an HVAC system after demolition of painted surfaces has taken place may find that to complete the job painted surfaces need to be disturbed. The HVAC firm may not engage in activities that disturb painted surfaces if it is not certified.  As every renovation job is different, it is up to the firm acting as the general contractor to determine what activities are within the scope of the renovation and to ensure that other firms are properly trained and certified for the tasks they will be performing. All firms, including the firm acting as the general contractor, are responsible for making sure the renovation is performed in accordance with the RRP work practice standards, including keeping containment intact and making sure lead dust and debris do not leave the work site. General contractors should keep in mind that if a firm hires a subcontractor that fails to follow the work practice standards or otherwise violates the Renovation, Repair, and Painting rule, the firm that hired the subcontractor is also responsible for the violation.

As every renovation job is different, it is up to the firm acting as the general contractor to determine what activities are within the scope of the renovation and to ensure that other firms are properly trained and certified for the tasks they will be performing. All firms, including the firm acting as the general contractor, are responsible for making sure the renovation is performed in accordance with the RRP work practice standards, including keeping containment intact and making sure lead dust and debris do not leave the work site. General contractors should keep in mind that if a firm hires a subcontractor that fails to follow the work practice standards or otherwise violates the Renovation, Repair, and Painting rule, the firm that hired the subcontractor is also responsible for the violation. If you are a certified renovator trying to figure out innovative, efficient and time saving production methods to protect profits on EPA RRP related projects you might want to consider a dust room.

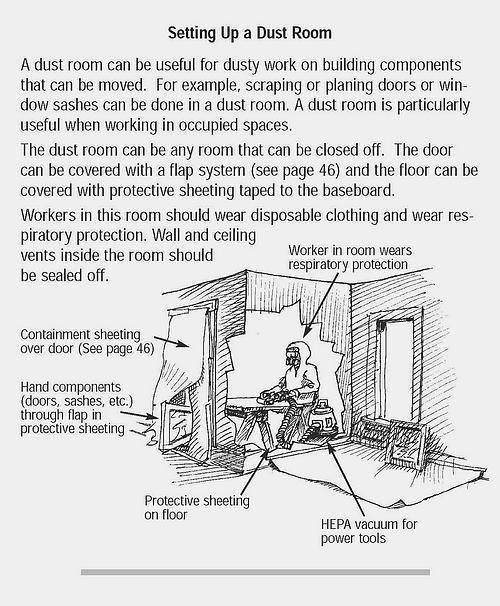

If you are a certified renovator trying to figure out innovative, efficient and time saving production methods to protect profits on EPA RRP related projects you might want to consider a dust room.