EPA Lead-Safe Certified Firm Logo Use Guidelines

Guidelines for use of the Certified Firm Logo provided by EPA must be followed to avoid fines. Reading and understanding the following information can help make sure you are in compliance if you plan to use the firm logo on your vehicles, signage and or any marketing you do.

What is the Lead-Safe Certified Firm Logo?

The Lead-Safe Certified Firm Logo identifies a firm as certified under the Renovation, Repair, and Painting (RRP) Rule. The colors used to make the two-color logo are Pantone 362C (green) and Pantone 660C (blue). The font is Helvetica.

What are the guidelines for using the Logo?

The Logo must be reproduced so that all of its components are legible and includes your firm's certification number. The Logo must not be altered or distorted in any way.

You MAY --

- Use the Logo to identify your firm as an RRP-certified firm. Firms that are not RRP-certified may not use the Logo.

- Use the Logo in brochures, advertisements, Web sites, proposals, bills, signs, uniforms, vehicles and other materials promoting or identifying your firm.

- Use the Logo on documents or other materials in black and white or color (two-color or four-color versions are available).

You MAY NOT --

- Use the Logo in any manner that would imply EPA endorsement of a company, its products or services.

- Reduce the Logo to a size smaller than one inch wide by 0.687 inches in height.

- Allow a firm that is not RRP-certified (including your subcontractors) to use the Logo.

EPA will monitor the use of all Logos. If necessary, EPA will address failure to comply with these Logo Guidelines. To report a non-compliant use of the Logo, please contact EPA at 1-800-424-LEAD.

EPA will e-mail information regarding your custom Logo to the e-mail address listed on your firm certification application.

For further questions regarding your EPA Lead-Safe Certified firm Logo, please send an email to: EPARRPFirmLogo@battelle.org or send a fax to: (202) 566-0470. In your email/fax please include your EPA Firm Certification number (e.g., NAT-12345-1), Application ID (e.g., 12345), firm name, and firm mailing address.

EPA Lead-Safe Certified Firm Logo - Information for Training Providers

Accredited training providers may use the Logo on their site and marketing materials as long as it is used as a tool to guide renovators through the firm certification process (i.e., explain the difference between firm certification and individual training). Training providers may inform students that only certified firms will be provided a customized Logo exclusively for their use to advertise their businesses once their firm has been certified. Training providers may distribute the Logo only to principal instructors affiliated with the accredited provider, and only for the purpose of training as described above. Training providers may NOT distribute the Logo to unaffiliated entities. Upon request, EPA will provide to accredited training provider the Logo for their use. Requests can be made to the National Lead Information Center at 1-800-424-LEAD.

Principal instructors that advertise, provide training, and use the Logo must do so under the name of the accredited training provider for whom they work. They may also state that the organization that employs them, if different from the accredited training provider, is assisting with the training.

Information for Press and Marketing Entities

Press and other marketing entities may use the logo on their site and marketing materials provided it does not include a certification number. They may NOT:

- Distribute or provide a downloadable version of the logo

- Indicate association, endorsement or approval from EPA

- Imply lead-safe certification from EPA or any EPA-authorized state.

Upon request, EPA will provide the logo for use.

Note: The information shown above is from the EPA web site. EPA has already and may again revise these guidelines. Use this link to find the most recent info at the EPA web site.

Looking for accurate information about the EPA RRP rule?

Looking for accurate information about the EPA RRP rule?

The information on and the format of each page varies. Some of the information found on the various pages may include:

The information on and the format of each page varies. Some of the information found on the various pages may include:

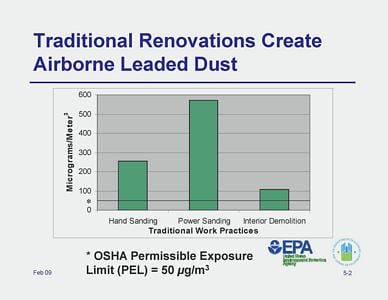

While at the workshop I found one thing the main instructor Darcy Cook of Safety Trainers said to be very important for contractors to be aware of. Under the OSHA Lead in Construction Standard, contractors must assume their employees will be exposed to lead above OSHA’s established action level requiring the use of respirators until they actually conduct air monitoring testing to prove otherwise.

While at the workshop I found one thing the main instructor Darcy Cook of Safety Trainers said to be very important for contractors to be aware of. Under the OSHA Lead in Construction Standard, contractors must assume their employees will be exposed to lead above OSHA’s established action level requiring the use of respirators until they actually conduct air monitoring testing to prove otherwise.

So, under OSHA requirements, before allowing them to do RRP related work or even enter a contained work area, employees must first be sent to a physician to be sure they are healthy enough to wear a respirator. Then they must be fit tested by a professional and provided with a properly fitted respirator that protects them from worst case lead exposure scenarios based on the kind of work they do. They must also be trained how to select, use, clean and store a respirator. And, they must wear the respirator until the air monitoring testing is done to identify when a respirator is required and when it is not depending on how the work is performed and what engineering controls are being used.

So, under OSHA requirements, before allowing them to do RRP related work or even enter a contained work area, employees must first be sent to a physician to be sure they are healthy enough to wear a respirator. Then they must be fit tested by a professional and provided with a properly fitted respirator that protects them from worst case lead exposure scenarios based on the kind of work they do. They must also be trained how to select, use, clean and store a respirator. And, they must wear the respirator until the air monitoring testing is done to identify when a respirator is required and when it is not depending on how the work is performed and what engineering controls are being used. Through my fellow NARI member contacts I have learned that on November 5, 2010, at their offices in Washington DC, the

Through my fellow NARI member contacts I have learned that on November 5, 2010, at their offices in Washington DC, the  Hybrivet Systems, Inc. and ESCA Tech, Inc. are the manufacturers of the only two commercially available

Hybrivet Systems, Inc. and ESCA Tech, Inc. are the manufacturers of the only two commercially available  At the meeting a representative from ESCA Tech, Inc asked the EPA when it was going to require that RRP training instructors demonstrate the proper use of both of the currently approved lead test kits at the EPA required Certified Renovator Training Classes. EPA responded that they were not going to require training on both kits and instructors could decide which kit they would demonstrate at the training.

At the meeting a representative from ESCA Tech, Inc asked the EPA when it was going to require that RRP training instructors demonstrate the proper use of both of the currently approved lead test kits at the EPA required Certified Renovator Training Classes. EPA responded that they were not going to require training on both kits and instructors could decide which kit they would demonstrate at the training.  Here is just one reason I will go with the Lead Check kits when I do RRP training. Using the D-Lead kits will definitely take longer than using the Lead Check kits. The certified renovator classes at eight hours long make for a long day and it is tough enough already for instructors to cover the subject matter in those eight hours. Demonstrating and using the D-Lead kits would either cause the class to go past eight hours, or time spent on other topics would need to be cut back to keep the day at eight hours. I know the students would rather not extend the day and I would prefer not to cut back on or eliminate any of the required subject matter.

Here is just one reason I will go with the Lead Check kits when I do RRP training. Using the D-Lead kits will definitely take longer than using the Lead Check kits. The certified renovator classes at eight hours long make for a long day and it is tough enough already for instructors to cover the subject matter in those eight hours. Demonstrating and using the D-Lead kits would either cause the class to go past eight hours, or time spent on other topics would need to be cut back to keep the day at eight hours. I know the students would rather not extend the day and I would prefer not to cut back on or eliminate any of the required subject matter.